Starting with the in-house development of the automatic register control system Alygn, which later was upgraded to AlygnAXIS, A.T.E. has over 250 installations worldwide. In 2016-17, the company launched web video, full print repeat web video and 100% print defect detection system.

Print and Packaging Equipment, the business unit of A.T.E. Enterprises, caters to the print, packaging and converting industries. Anand Mehta, vice president, Print & Packaging Equipment, A.T.E. Enterprises Private Limited said, “Today, we are one of the few manufacturers of register controllers for rotogravure presses in India. Most OEMs in India manufacturing rotogravure presses use A.T.E.’s register controllers. A.T.E. also handles a lot of retrofit work wherein the older rotogravure presses are fitted with register controllers, especially with automation coming into the industry in a big way. The exports market is another major thrust area for us.”

Register controllers have been the mainstay of PPE during the initial years; however, new product additions include a range of vision systems to monitor print during production runs. The range includes two variants at the moment, ViewAXIS Mega and ViewAXIS Tera. ViewAXIS Mega is an entry-level video system.

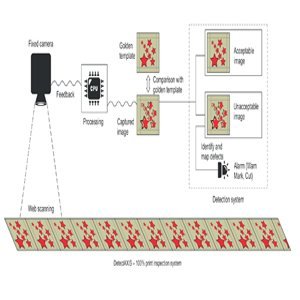

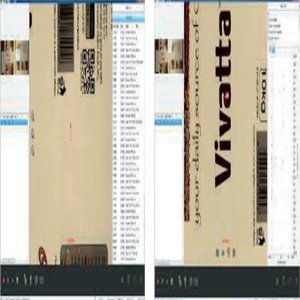

The ViewAXIS Tera is an unique product which shows a full print repeat on the screen. The 55” 4K monitor displaying images of 50+ megapixels resolution results in ‘near-print quality’ visualization. Besides the web video systems, the ISO 9001:2015 certified organization A.T.E. also manufactures DetectAXIS – a 100 % defect detection system.

In many industrial applications excessive presence of static electricity can create issues like shocks to operator, dust/dirt accumulation and reduced productivity, and fire hazards. Hence, during a production run, such static charges need to be neutralized. Valence offers static charge eliminators that are deployed for effective static charge removal.

In many industrial applications excessive presence of static electricity can create issues like shocks to operator, dust/dirt accumulation and reduced productivity, and fire hazards. Hence, during a production run, such static charges need to be neutralized. Valence offers static charge eliminators that are deployed for effective static charge removal.

Valence is the only Indian company to offer ATEX certified static bars which are certified for use in explosion prone areas. These are highly efficient static eliminating bars, designed for neutralizing electrostatic charges from fast moving films, paper and other non-conductive substrates (webs) in hazardous conditions.

Another significant product group from Valence is ink-handling and conditioning systems, for rotogravure and flexographic printing presses. In the ink handling area, Valence offers pumps, filters and ink tanks for efficient ink circulation. For ink conditioning it offers the Ink temperature stabilizer (ITS). ITS cools the ink to ensure that ink temperature is maintained at optimum levels during the production run. This reduces evaporative or fugitive loss of solvents, improves ink transfer and reduces solvent odor on the shop floor. The third product group is recovery of waste heat. The rotogravure printing, coating/laminating as well as extrusion coating machines needs heat as a process requirement. Waste heat

Another significant product group from Valence is ink-handling and conditioning systems, for rotogravure and flexographic printing presses. In the ink handling area, Valence offers pumps, filters and ink tanks for efficient ink circulation. For ink conditioning it offers the Ink temperature stabilizer (ITS). ITS cools the ink to ensure that ink temperature is maintained at optimum levels during the production run. This reduces evaporative or fugitive loss of solvents, improves ink transfer and reduces solvent odor on the shop floor. The third product group is recovery of waste heat. The rotogravure printing, coating/laminating as well as extrusion coating machines needs heat as a process requirement. Waste heat

from the exhaust stream is recovered and recycled for preheating the air used in the process, resulting in energy saving. The fourth specialization of Valence is surface cleaning and removal of surface contaminants like dust and lint from various substrates like from paper, film and foil.

This range of specialized solutions from A.T.E. and Valence is witnessing growing demands as the Indian market is striving for higher levels of operational efficiency, quality, and safety.

It is the only Indian company to offer ATEX certified sensors on AlygnAXIS, the register control system, ensuring safety of use in explosion prone areas. The made in India ViewAXIS Tera with line scan camera captures high-resolution images which are then visualized on 55” 4K monitor and for operation on 22” touch monitor. It is bundled with features such as instant error identification, better image control, and precise web monitoring.

A.T.E.’s DetectAXIS is a 100% print defect detection system for various applications including rotogravure and CI flexo presses, among others. Using line scan cameras of more than 150 DPI, even the tiniest of errors are identified with a resolution of up to 0.01 mm at production speeds up to 500 mpm. When a defect is spotted, DetectAXIS generates alarms and electronically tags the defect, consequently bringing to the operator’s attention that corrective action is needed. The system displays the defect snapshot with defect location on the screen making it easy for the operator to spot. It ensures defect free, high quality print output.