To keep pace with the market’s insatiable appetite for productivity, printing presses are being asked to achieve higher and higher speeds. Unfortunately, as you increase speed, you’re faced with a disproportionate increase in vibrations. To compensate for these disturbances – and allow even the fastest presses to print with impeccable quality – B&R has developed a set of advanced control functions.

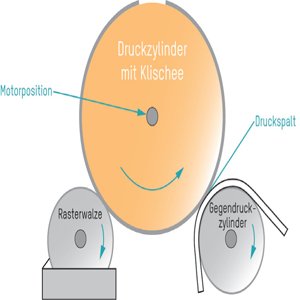

The level of quality that a flexographic printing press is able to achieve depends heavily on how well it can synchronize the web on the impression cylinder with the plate on the printing cylinder. Highly precise positioning at the nip is crucial. “A conventional press is a relatively rigid system, so the motor’s encoder signal is sufficient to control the printing process,” explains Dr. Engelbert Grünbacher, head of B&R’s motion control firmware development team.

A growing number of today’s printing presses feature a streamlined mechanical design that utilizes lightweight materials. The resulting elasticity of these systems means that the motor position is not perfectly aligned with the target position at the nip during operation. Disturbances and vibrations also have a stronger impact on image quality.

synchronize the web on the impression cylinder with the plate on the printing cylinder.

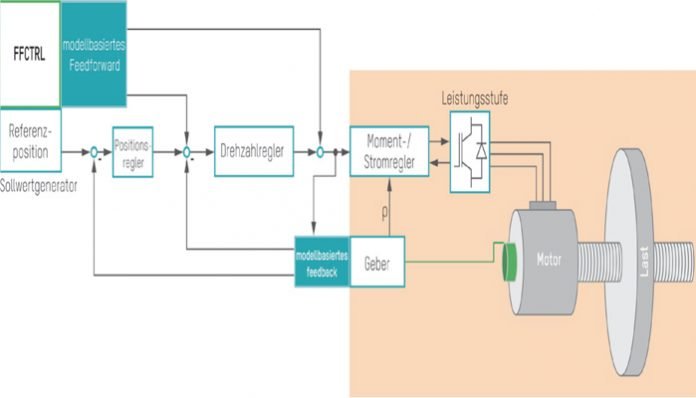

To mitigate these sources of error, B&R’s servo drives offer the new High Precision Motion Control. “This solution encompasses three key technologies: virtual sensing, model-based control and predictive disturbance rejection,” explains Grünbacher. Each of these features can be implemented and configured independently of the others. B&R’s newest servo drive, the ACOPOS P3, is perfectly suited for High Precision Motion Control. Its fast 50 microsecond sampling time ensures that the advanced control functions are executed effectively.

When the process is dynamic and positioning is critical, you need a motion control solution with exceptional speed and precision. With its fast 50-microsecond sampling times, B&R’s ACOPOS P3 servo drive is the perfect home for advanced control functions like High Precision Motion Control.

Active disturbance rejection

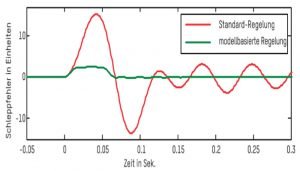

Since the printing plate doesn’t cover the full circumference of the printing cylinder, the resulting gap produces a fixed-position disturbance torque that results in lag error. Even the print profile itself produces a certain amount of disturbance torque. “Fine-tuning the drive parameters can minimize this lag error, but will not be able to completely prevent the disturbances,” says Grünbacher.

All of B&R’s ACOPOS P3 and ACOPOSmulti servo drives offer a function called Repetitive Control – an adaptive, predictive method of suppressing periodic or fixed-position disturbances. After measuring and analyzing the disturbance, the drive is then able to smooth out the motor torque.

This compensation occurs automatically, minimizing lag error without tedious parameter tuning or mathematical models. The result is improved speed stability and print quality.

Virtual measurement of target position

In order to suppress periodic disturbances, you need to be able to determine the target position with high resolution. On an elastic mechanical system, that used require an additional sensor. With virtual sensing, however, there are new possibilities.

Virtual sensing involves using easily measurable system variables and a model of the system to calculate the values of other variables that are more difficult to measure. “To approximate the behavior of a direct-driven printing cylinder, we can use a simple two-mass system,” explains Grünbacher. “The motor and printing cylinder are joined by a shaft, which for the sake of our calculations we will assume is flexible and massless. A torque proportional to the angle of rotation is generated in the shaft.”

The speed and position of the motor are easy to measure, and the motor torque is known. If we use these known values to calculate the hard-to-measure speed and position of the load, what we have is a virtual load position sensor.

Highly dynamic drive control

With a virtual sensor, we can determine the target position without actually measuring it, and use the results to suppress periodic or fixed-position disturbances. This only applies to quasi-stationary processes. Often in the printing industry, drive systems are subject to highly dynamic requirements. “This is where

model-based control comes into play,” notes Grünbacher.

A highly dynamic control solution for elastic systems is composed of modelbased feed-forward and feedback elements. Depending on the area of application, these elements can be used individually or in combination. The model-based control loop is incorporated in the standard cascade control structure.

The model-based feedback controller includes a virtual sensor and a state controller. The state controller accounts for the state of the overall system – consisting of the motor position, motor speed, load position and load speed – making it possible to detect and actively suppress torsional vibrations. This greatly reduces the tendency of elastic systems to vibrate. “The adverse effect of disturbance torque on print quality is minimized,” says Grünbacher.

Preventing vibration

Vibrations can result not only from disturbances on the cylinder surface, but also from rapid changes to the position setpoint. Model predictive control can bring substantial improvements here as well. Based on the mathematical model, the motor torque is regulated so that the target position follows the position setpoint without overshooting. The desired behavior is achieved with excellent dynamic performance. The comprehensive range of High Precision Motion Control functions available on B&R’s ACOPOS P3 and ACOPOSmulti servo drives provides all the tools needed to maximize performance, even in elastic mechanical systems. For a printing press, this equates to higher productivity paired with optimum print quality.