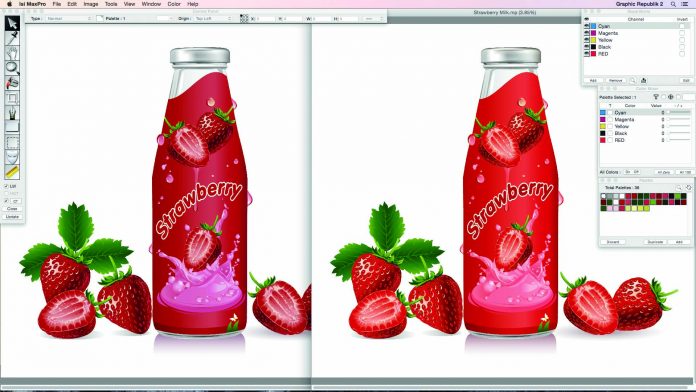

We’re starting to see a lot of digital options being introduced in the packaging sector, particularly on the labelling side. Indeed, we’ve already reported on the rise of hybrid inkjet and narrow web flexo presses that were shown at the last couple of Labelexpo shows and we’re fully expecting to see a number of much wider inkjet and hybrid presses at this summer’s drupa show. In addition, extended color gamuts could offer savings in both time and materials to flexo printers. In most cases, digital printing in the packaging sector is introducing a short-run alternative to flexo printing. But flexo printing is characterized by the heavy use of spot colors, both to pick out company logos and to make images more vibrant. There is an alternative – to use a fixed color gamut, sometimes known as extended gamut color printing. It’s not a new idea, dating back to Pantone’s Hexa- chrome offering from the mid-90s. But its adoption has been held back, mainly because converters want to offer the best image possible and that usually…

Choose your subscription to read more

Trial

- ₹ 0 for 4 weeks*

PSA Plan 1

- ₹1,500.00 for 1 year*

PSA Plan 2

- ₹2000 for Year*

PSA Plan 3

- ₹3,600.00 for 2 year*