Ten years ago, Heidelberg and MK Masterwork, China’s leading manufacturer of finishing systems for the packaging sector, agreed on a strategic sales partnership. As part of this, Heidelberg distributes high-performance die-cutters as well as folding carton gluers and hot-foil stamping machines from MK Masterwork outside of China.

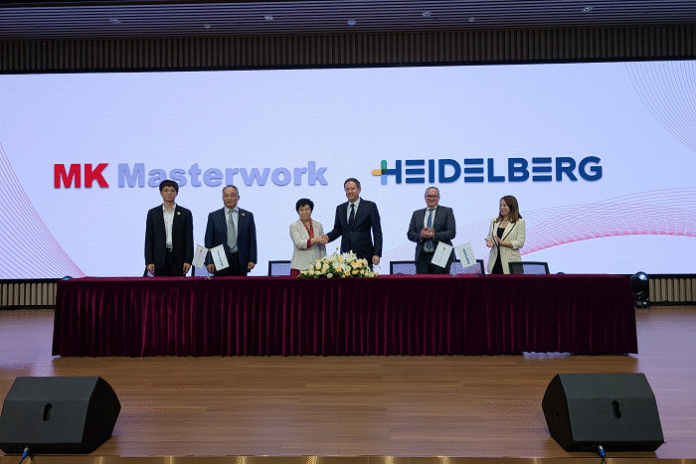

Since then, Heidelberg has installed around 1,500 systems produced by MK Masterwork at customer sites around the world. Now, at a joint anniversary event at MK Masterwork’s headquarters in Tianjin with around 100 international customers, both companies looked back on the milestones of their long-standing successful partnership.

At the same time, both are looking ahead to their shared future: During the celebrations Heidelberg an MK Masterwork signed an agreement to extend and expand their cooperation in the field of integrated and highly automated complete solutions, which can also be developed in collaboration with customers.

This also includes the integration of MK Masterwork’s robotics systems, which are becoming increasingly important for packaging manufacturers, particularly for intralogistics. In many companies they make an important contribution for a higher productivity and a further reduction of personnel costs.

“Packaging printing is a central component of our growth strategy for our core business,” says David Schmedding. “And our cooperation with MK Masterwork is a long-standing success story. We are now renewing and expanding this strategic partnership, thereby underlining our approach as a system integrator for end-to-end packaging production. We offer our customers efficient complete solutions and at the same time tap into further potential in the attractive segment of packaging finishing.”

“Thanks to our innovative and economical technologies, MK Masterwork has continued to grow dynamically in recent years and has already become the market-leading provider of packaging finishing solutions in China,” said Li Li. “Together with a strong partner like Heidelberg, we have succeeded in advancing to become one of the leading providers in this segment worldwide. Together, we will continue to expand our strong market position.”

MK Masterwork has been growing dynamically for years and now employs more than 1,800 people. The production site in Tianjin, China, covers an area of around 600,000 m2. At the Print China trade fair in May this year, the company also celebrated its 30th anniversary.

Milestones from 10 years

In the end of 2014, Heidelberg and MK Masterwork agree on a strategic sales partnership with Heidelberg becoming the sales channel for MK Masterwork products outside China. In 2016, at drupa 2016, both companies appear together for the first time with a joint booth and present a comprehensive range of flatbed die cutters, folding carton gluing machines and hot foil stamping machines for the packaging sector.

In 2019, MK Masterwork becomes largest anchor investor of Heidelberg with the acquisition of approximately 8.5 percent of voting rights. Then in 2020, Heidelberg and MK Masterwork establish a joint venture for the development and production of precision machine parts for the Heidelberg plant in Shanghai.

In 2025, a presentation of the updated MK Mastermatrix 106 CSB high-performance die cutter with Prinect integration in Heidelberg design marks a major step toward automated end-to-end production in packaging printing. To date, Heidelberg has successfully installed around 1,500 MK Masterworks systems worldwide.

Both companies are renewing and expanding their strategic partnership to offer integrated and highly automated complete solutions for packaging production.