We recently interviewed Dr David Schmedding, the chief Technology and Sales officer of Heidelberg in Mumbai on his tenth visit to the country. Keen to build a bridge between Germany and India, he had brought a delegation of commercial and packaging printers from Germany who visited several print and packaging plants near the city.

The German printers took part in the interesting one-day HeiConnect industry conference on 29 January 2026 which was also addressed by Heidelberg’s leadership in Germany, Switzerland, Asia and India. Schmedding’s openness in our meeting reflected the company’s new and more considered look at India. Edited excerpts from our conversation follow.

Naresh Khanna, editor, Packaging South Asia – Dr Schmedding, what is the overall outlook for the manufacturing, integration, and sales of equipment for the printing and packaging industry globally, and regionally? Is there, for instance, really enough market growth potential for the five major offset press manufacturers to continue as standalone companies?

Dr Schmedding – Print production volumes are relatively stable worldwide, and in offset, while we see growth in packaging, in commercial print we see a shift from offset to digital. The overall value of print is growing slightly, but the market is changing. There is a geographic change from industrialized countries to other regions including India, which is a growing market.

In the end, to answer your question if the market is big enough for the five large players, the sheetfed offset press market is not really big enough. We have to consolidate the market, and probably there isn’t room for five players anymore. The consolidation of the market is normal.

Heidelberg is the biggest player among the five companies, and apart from our factories in Germany, we are the only one of these five with a factory in China. Our Shanghai factory produces machines not only for China but for the whole world, and this gives us a big advantage.

As far as India is concerned, we have to definitely increase our business here by investing more and getting back to our strengths. Maybe the competition is doing well in some respects, but with the increasing pressure of competition, and our strengths, including our factory in China, these could help us to dominate the market.

PSA – Do you see manufacturing in China, particularly in Shanghai, as only for the Asian or emerging markets, or is it possible that manufacturing there will grow with more technology transfer and higher-tech machines coming from there? Also, do you see the need for improving efficiencies in your European operations?

Dr Schmedding – As far as what is produced in our factories in Germany and China, we are driving the product portfolio according to the regional demands of the market. The XL 75, 105, and 106 high- performance presses are coming from Germany, while the Heidelberg factory in Shanghai is making increasingly automated and bigger presses, which have been installed in over 70 countries globally, including Italy and Germany.

We are now producing highly customized presses in Shanghai, and in recent years, we have delivered more than ten long presses from the China factory that are 14, 15, and 16-color presses. These are special configuration presses for high-value packaging. We would shift more automation technology to Shanghai if customers in China or Asia were demanding these, and as I said, we are driving the product portfolio according to regional demand.

Apart from our relationship for packaging converting machines, we have a new joint venture company with Masterwork in Tianjin for manufacturing components. This company’s highly automated plant is already in production. We continue to manufacture components in Germany in operations that are also highly automated.

As far as efficiencies are concerned, we have to lower production costs in Germany to make our products more attractive, especially for price-sensitive markets like India. Even if customers are willing to pay more, the difference has to be reasonable, and we have taken some productivity measures in the last year. Still, we are investing more in automation in both Germany and China.

PSA – Would you care to comment on your increasing partnerships with OEMs and the new CX 145 press? What is its potential market, particularly in Asia?

Dr Schmedding – We have been the leader in hybrid solutions with offset and digital presses for many years. We are a system integrator, and as a provider of full solutions for packaging and commercial print, and since we cannot do everything on our own, we have to work with other suppliers, integrate, and fill the gaps. We are doing this with Canon since drupa 24, as we have been doing with Ricoh for more than ten years.

Our strategy is not just to be a machine provider but to provide a full range of solutions to our customers, and that is why we decided to partner with Manroland Sheetfed. In packaging, we were lacking a very large format press, an area we decided to step out of, for economic reasons a few years ago. Now we are back with the CX 145 based on the Manroland Sheetfed press.

While Manoroland is the supplier, the sales, service, and integration will come from us, and we are planning to show the Heidelberg CX 145 to the public this summer. With the core software and front end from Heidelberg, and our extensive global presence and supply chain for spare parts and service support, we can offer this machine to a larger number of markets. However, we see the US and China as the leading VLF markets, and perhaps a few presses may come to Asia and India.

PSA – Would you care to comment on how the US reciprocal tariffs have affected Heidelberg?

Dr Schmedding – We received good orders from the USA in October-November [2025], but there are challenges. While for most products the tariff is 15%, for flexo machines there is an additional 50% tariff, and that only for the aluminum components. Some other tariffs depend on the type and source of the raw material, which is really a complicated and challenging topic. It is not just about the tariff number but more about the complexity and the tediousness of the detailed documentation.

PSA – Since Heidelberg is collecting data from over 11,000 of its connected machines globally, which can lead to improvements, including in OEE, has there been any particular work where the data explains and can remedy operational or day-to-day issues in particular markets? How many of these connected machines are in India?

Dr Schmedding – There are 11,000 machines connected worldwide, which help to improve our service. We are not just collecting data, but we are trying to improve our customers’ efficiency. In large countries such as India, it helps especially for remote service. We have implemented a customer portal for printers to see and benchmark their productivity in comparison to others, and to benefit from tools that have artificial intelligence. They can learn how to reduce waste and how to reduce makeready times.

The Indian potential to increase productivity is huge, but so far, the number of connected machines is in the low three-digit numbers. For India, remote is the key. There are many machines in India, but some are as old as 60 years, and although there are ways to connect them, this is a challenge.

PSA – The new Boardmaster press seems like it could be very productive, especially for liquid aseptic packaging. Has it found any traction there, or in other types of packaging?

Dr Schmedding – This is a high productivity machine with a 600 meters per minute speed, offering 90% availability because of its automation features. We have sold it worldwide, and the order book is full. It is gaining traction with ten machines sold mostly in the past 18 months to North America, China, and Africa. These have gone mainly to liquid aseptic carton producers, which is one of the key applications, and also for secondary packaging cartons for beverage cans.

This is really a customized machine capable of inline spot coating for barrier and inline die-cutting, which are useful for sustainable fibre-based packaging. In many markets with large populations, the Boardmaster can be appropriate for food service products.

PSA – Are there any plans or ideas about Heidelberg’s approach to the Indian market or to its ambitions in other sectors that you can share? It seems that your company’s outlook on India has shifted a bit.

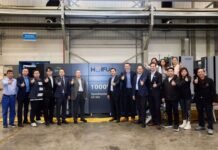

Dr Schmedding – There is a geographic shift in markets, and I believe there is a strength in the Indian market that we can explore further. I want to build a bridge between Germany and India, and this is why we have brought some German customers to see the high level of printers and packaging companies here. High quality, high productivity, and well–organized modern print shops. They can see that the leading Indian printers are at the same level as German printers. Seeing is believing, and we also want the Indian printers to meet the German printers face to face and to be able to interact with them.

We want to build bridges for interaction and traffic in both directions. We want to invest in India, and this is not only in people and other resources. We are looking at the opportunities and possibly manufacturing something in India, as well.