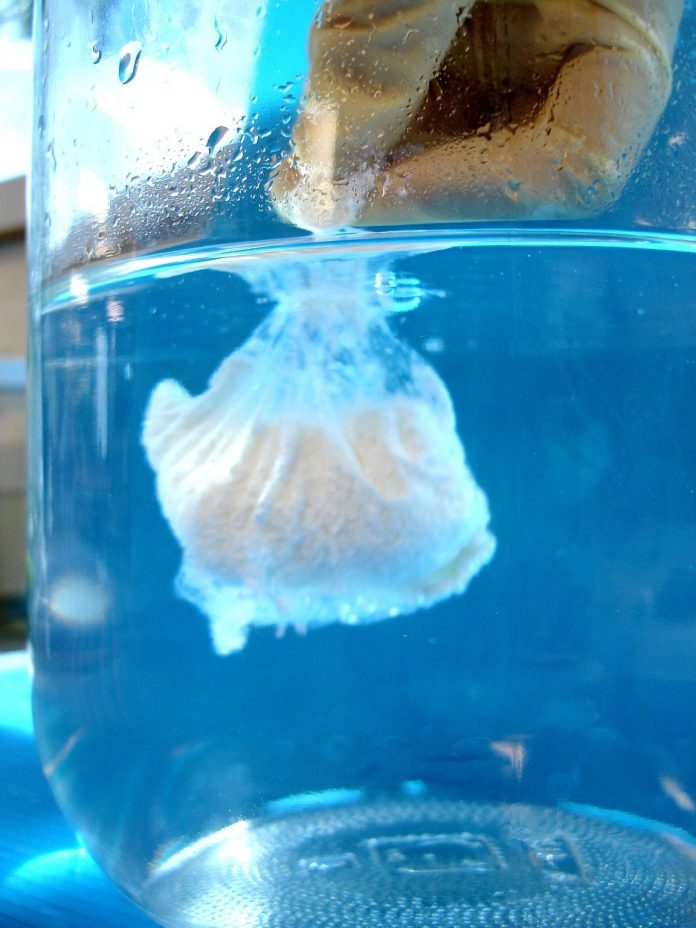

EcoCortec’s team announced that patented EcoSol water-soluble pouches would be available from EcoCortec, Cortec’s European bioplastics plant located in Croatia. According to the company, this will enable prompt delivery of custom made pouches to our European and Asian customers. Vibrant EcoSol technology represents the latest generation of packaging solutions. This water-soluble, biodegradable, polyvinylalcohol (PVOH) film is suited for various packaging applications. Water-soluble PVOH bags, sachets, or pouches created from this film provide a convenient, safe, and economical delivery system for a wide range of products; including detergents and cleaners, degreasers, concrete additives, pigments, biocides, water-treatment products, agricultural products, and others. EcoSol film claims to have a good organic solvent resistance, which allows EcoSol pouches and bags to be used not only for dry powders but also for liquid products. EcoCortec said this innovative film offers very good mechanical properties such as tensile strength, tear strength, and puncture resistance. These properties allow EcoSol to be used in a wide variety of rigorous applications. Products packaged in EcoSol can be thrown into a treatment area without removing…

Choose your subscription to read more

Trial

- ₹ 0 for 4 weeks*

PSA Plan 1

- ₹1,500.00 for 1 year*

PSA Plan 2

- ₹2000 for Year*

PSA Plan 3

- ₹3,600.00 for 2 year*