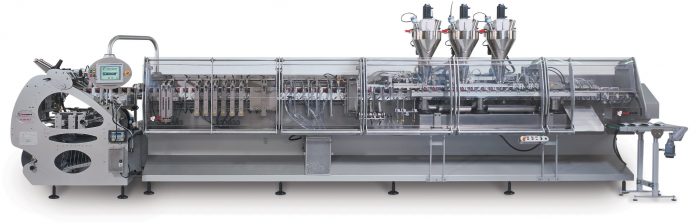

Flexible packaging, while fast-growing, is also fast evolving with better decoration, barrier properties, and sustainability. New and innovative methods continually offer more attractive packs, extended product protection, and shelf appeal. Mespack, headquartered in Barcelona, Spain, is a flexible packaging machine manufacturer that engineers and builds high-speed form fill seal machines for food, beverage, pharmaceutical, chemical, confectionery, cosmetic, and personal care sectors. Mespack started its Indian operations at Thane, a Mumbai suburb in 2012 focusing on end-of-line localization, sales, and integration. “At Mespack, we seek packaging innovations and believe in giving new concepts and technologies to our customers,” says Anthony D’souza, managing director, Mespack India. Anthony D’souza, managing director, Mespack India The company has a broad portfolio of packaging solutions in horizontal and vertical form fill and sealing machines, end-of-line, forming, filling and sealing sachets, stick pouches, flow packs, thermoforms, and others. Mespack India offers these solutions to Unilever, L’Oreal, Godrej, Mylan, Lupin, and many others. D’souza asserts, “Even though the most expensive in the market, we sell the most machines. We are known for the…

Choose your subscription to read more

Trial

- ₹ 0 for 4 weeks*

PSA Plan 1

- ₹1,500.00 for 1 year*

PSA Plan 2

- ₹2000 for Year*

PSA Plan 3

- ₹3,600.00 for 2 year*