Fujifilm will exhibit its extensive portfolio of analog and digital packaging solutions at Interpack under the theme of ‘Analogue. Digital. Sustainable’. Recognizing how print can add value to packaging, Fujifilm is combining its expertise in the latest digital print technologies with an analog heritage to create a unique portfolio that supports the production of both analog and digitally printed packaging, all while demonstrating a commitment to sustainability.

The company is at stand F65, Hall 8a, from 4-10 May 2023.

Analog solutions

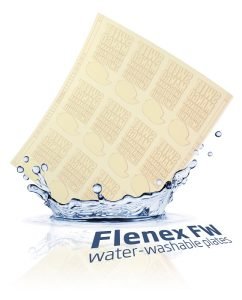

Fujifilm will showcase its Flenex FW water-washable flexo plates that eliminate environmentally harmful solvents often used in the plate-making process and are more durable than most alternatives, meaning fewer plate changes and less waste. The sustainable benefits go hand-in-hand with greater press stability and higher, more consistent quality.

Also on the stand will be Fujifilm’s range of narrow web inks, which it has been manufacturing for many years, and which have earned a market reputation for both quality and versatility.

In addition, Fujifilm’s retrofittable LED UV curing system will be on the stand. The system uniquely combines both LED UV curing hardware and a brand-new range of LED UV inks, radically reducing energy consumption, eliminating harmful VOCs, requiring lower maintenance, and producing less waste. This results in lower costs, along with higher, more consistent quality.

Digital solutions

The Jet Press 750S high-speed model, which has set a new standard for print quality whatever the technology, will be running live on the stand, producing folding carton packaging in conjunction with a Kama finishing unit. Well-known in the commercial print sector, it is also designed to print short-run, folding-carton packaging at exceptionally high levels of quality, with many customers using it exclusively for this purpose.

Fujifilm offers a wide range of scalable imprinting systems that bring the benefits of digital printing to analog processes by combining Fujifilm’s proprietary technologies across printheads, inks and transport systems with the company’s in-depth integration expertise. Based on Fujifilm’s world-leading Samba piezo-electric printbars, the company’s imprinting solutions allow digital inkjet printing to be integrated directly into existing analog production lines for a broad range of industrial applications.

The Jet Press FP790 digital flexible packaging press will also feature on the stand. Built on decades of Fujifilm inkjet expertise, the Jet Press FP790 is designed to offer a digital alternative to flexo production for mainstream applications and print runs and meets the strategic needs of businesses faced with the challenge of dealing with the proliferation of SKUs, a widening variety of products and shorter delivery times.

Sustainable business

Across both analog and digital solutions, Fujifilm will also be demonstrating how packaging businesses can be more sustainable. Fujifilm’s Flenex plates, for example, reduce waste and eliminate the use of environmentally harmful solvents altogether, and when combined with the company’s PRC1 filtration unit, also minimize water. Fujifilm’s LED UV curing system slashes energy use, and the company’s narrow web inks are solvent-free and manufactured in the UK at Fujifilm’s award-winning Broadstairs factory, where extreme care is taken to ensure all manufacturing and operational processes are as environmentally responsible as possible.

Similarly, Fujifilm’s imprinting solutions can breathe new life into an analog production line, bringing additional functionality without the investment in a new line. Where a new investment is necessary to meet market needs, the Jet Press 750S and Jet Press FP790 digital presses eliminate many of the processes and consumables associated with traditional analogue production. Much has also been written about how the Jet Press 750S can contribute to a more circular economy.

Manuel Schrutt, Head of Packaging, EMEA says, “We are delighted to be exhibiting at Interpack 2023, the flagship show for the global packaging industry. It’s great to see the show finally back up and running, after a long 6 years. We are looking forward to connecting with our existing and potential customers.

We work with packaging producers at all stages of their journey, whether it’s helping them to optimize analog production lines to maximize efficiency or to introduce a digital capability. We don’t do one-size-fits-all – we do the right solution, for the right producer, at the right time. And all our solutions, whether analog, digital, or somewhere in-between, are designed to reduce waste and the use of environmentally harmful chemicals, minimize energy consumption, and to be as sustainable as possible.”