“If your white ink isn’t opaque enough, just add more of it, right?” Not so fast! A recent comprehensive flexo print trial reveals surprising results about the importance of anilox engravings in achieving target white ink opacity. Not only do some engraving geometries deliver better-formed ink laydown, but they can achieve higher opacity with less ink volume. A look at the science of opaque white ink printing shows open-channel engravings can deliver better-quality results, faster turnaround, and reduced ink costs.

Just as the colors of an oil painting rely on a well-primed canvas for vibrancy, flexo-printed colors also depend on opaque white ink for hue accuracy and coverage. White ink that’s insufficiently opaque can render colors dull and fail to mask packaging contents. However, the usual remedies of adding more ink, ‘double bumping,’ or increasing pigment load are now shown to be wasteful and time-consuming and unnecessary if Apex GTT anilox engravings are used.

The high cost of white ink opacity and the test

Most flexo printers spend, on average, 30% of their ink budget on opaque white. The white ink surface area of an industry-average print job is 40%. So if a plant runs two presses 24 hours a day, the average annual cost of white ink alone may be around €500,000 (over Rs 40 lakhs). While every flexo shop is different, even incremental improvements can add up to sizable savings.

That’s why the head of print for the Vienna, Austria plant of leading flexo printer Coveris decided to test four different anilox engravings to learn what, if any, impact they had on opacity, ink consumption, and plate pressure.

Battle of the Anilox – Running a W&H Novoflex CM10, a live production test was set up wherein the only variables were the four different anilox engravings. The chosen test design was a customer order with a run the length of 160,000 meters, which was broken into four separate runs of 40,000 meters for each anilox test. The ink surface area coverage used 20% of solvent-based opaque white ink.

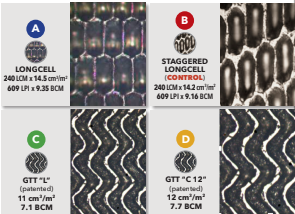

Each of the four anilox rolls is standard, commercially available engravings. The staggered long-cell engraving (B, below) was the ‘control’ roll in production use by Coveris. Apex International supplied the other three engravings as test rolls: 60° longcell (A), GTT ‘L’ open-channel (C), and GTT ‘C12’ open-channel (D). Since the plate, mounting tape, ink, viscosity, substrate, press speed, and machinery were all identical, the joint Coveris and Apex team who measured the results could conclude that any quality differences in print were exclusively due to the different anilox engravings.

But first, what do we mean by ‘Opaque’? The opacity of white ink is physically measured by the amount of light transmitted through an ink layer. But that’s only half the story: this ink layer’s compactness or ‘homogeneity’ determines the ‘quality’ of the opacity. An unusually thick layer of white ink might still have comparatively low opacity due to poor ink layer formation — i.e., low homogeneity. This translates on-press into mottling, pin-holing, and orange-peeling.

A typical cause of pin-holing is the aeration of the white ink liquid. Air is introduced into the ink chamber via the closed hex cells of an anilox surface upon ink replenishment (which may also create ink foaming) and also remains within the cell. Small quantities of air are thus carried along with the ink onto the substrate. As the ink dries, any air bubbles leave behind voids which create an uneven ink surface layer, often revealing the substrate. The ‘homogeneity’ of the ink layer is thus compromised, causing opacity reduction.

Test Result Surprise – Anilox Volume ≠ Opacity Conventional wisdom implies that higher anilox volume translates into higher ink consumption and thus higher opacity. ‘FALSE,’ replied the test results — on both counts. When all the test metrics for the four separate anilox engravings were charted, it was the Apex’ GTT-L’ (C) — the anilox engraving with the lowest ink usage (25.5 kilograms), correct target opacity (48.1% out of 48%), and second highest-quality ink formation — which had the lowest anilox volume measurement (11cm3 /m2 ).

The difference? This Apex ‘GTT-L’ engraving (C) employs an open-channel slalom geometry, not a closed-hexcell engraving.

The ‘control’ staggered longcell engraving (B) with 14.2cm3 /m2 volume paradoxically had the second-lowest ink consumption (26.5 kilograms) but also the lowest opacity (43%), which failed to meet its target of 48%. The other longcell engraving (A) had the highest anilox volume at 14.5cm3 /m2, achieved target opacity, and used the second-highest amount of ink (29 kilograms) with notable pin-holing. The other GTT open-channel engraving (D) had only a 12cm3 /m2 volume but used the most ink (31.5 kilograms), had the highest opacity (49.5%), and the best ink formation.

Geometry Matters- What can a printer surmise from these results? In the case of the longcell ‘control’ roll (B), a clean, high-volume engraving that counter-intuitively delivers low ink consumption and low opacity indicate that not enough ink reaches the substrate. The high amount of pin-holing suggests that the cell geometry contributes to ink aeration. With longcell roll (A), ink consumption, volume, and opacity are in logical alignment, but pin-holing degrades the ink layer – most likely, again, due to closed-cell engravings’ tendency to aerate the ink and leave ink behind within its cells.

In the case of the open-channel GTT engravings (C) and (D), the opacity was on target, and so too was ink homogeneity, as shown by the compact, non-pin-holed ink layer. But why, exactly, does GTT transfer ink better?

The Calming Effect of GTT The function of the anilox is to transfer a measured amount of ink to the plate surface as if each cell is a measuring cup. Air replaces the ink during this transfer, and in the case of closed-cell engravings, this air may not be fully displaced by ink upon re-entering the ink chamber nor removed during doctoring.

Open-channel geometry allows ink to ‘flow’ within its channels, avoiding compressive turbulence from the doctor blade. These channels are between 30%–40% shallower than closed cells. What’s more, GTT engravings have 66% less ‘land’ area (the top surface of a cell or channel walls) compared with closed cells, meaning more ink surface area is exposed to the plate. These rivers of ink easily lift out for transfer when the plate contacts the anilox.

But more importantly, since there is little — if any — air trapped within the ink, GTT’s ink homogeneity remains intact. Upon re-entering the chamber, an empty GTT channel area cannot carry along any air due to the positive ink pressure within the chamber — the open channels provide the air an ‘escape route.’ But with closed cells, the ink chamber cannot fully displace a cell’s air with ink during replenishment, resulting in poor homogeneity. This raises the conventional closed-cell predictability question: exactly how much of a closed cell’s volume contains ink versus air during production?

The Big GTT Win – Better Results, Less Ink Coupled with its improved opacity and ink laydown quality, GTT’s reduction in ink usage proves its value. Against the control roll (B), GTT delivered 4% ink savings and achieved target opacity. Notably, control roll (B) didn’t reach its target of 48, achieving only 43. Against the other closed-cell anilox (A), GTT delivered 12% ink savings. If a converter annually spends $1 million on ink per press, potential white ink savings could reach US$ 36,000 (Rs 2,63,000) per press per year.

Visually, GTT’s results practically eliminated pinholing and mottling, providing a higher-quality foundation for color printing. Moreover, GTT’s delivery of a thinner, more homogenous layer of white ink that dries quicker may, in turn, enable faster press speeds. The need for ‘double bumping could be eliminated altogether — depending on job specifics — resulting in savings on plates, set-up, and downtime.

For printers seeking reliably homogeneous, high-quality, and consistently opaque white ink laydown, GTT proves worthy of consideration — especially if cost reduction is a motivating factor.