Two decades ago, Heidelberg made a bold and far-reaching statement when it broke ground for its own production site in China. This was the beginning of a success story that has developed into a cornerstone of the entire company. The 2024/25 financial year set a record, with around 1,500 printing units assembled, an export quota of 40 percent, and deliveries to 70 countries.

To date, a total of over 16,000 printing and coating units and almost 3,300 printing presses have been delivered from the Shanghai plant. The site thus makes a significant contribution to the strong market position of Heidelberg in China and gives the company a real competitive advantage.

What began in 2005 with the assembly of simple folding machines for print finishing has now become one of the most important production sites in the global Heidelberg network as a result of the dynamic growth of the Chinese printing industry.

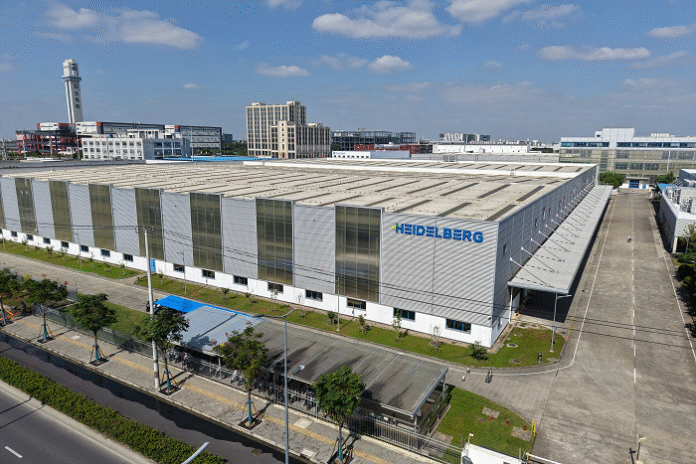

The Shanghai site (formerly known as the “Qingpu site” based on its exact location) covers an area of around 100,000 square meters, including 70,000 square meters of production space spread across three assembly shops. Today, the site employs around 600 people, who mainly produce printing units for the medium and large formats of the Speedmaster CX 92, SX 102, and CX 104 models.

With the opening of the Print Media Center at the Shanghai site in 2015, it has also developed into a center of excellence and a point of contact for customers from the Asia-Pacific region. Here, they can watch the machines in action, receive training, and see the site’s capabilities for themselves.

“Our Shanghai plant is particularly representative of the growth strategy of Heidelberg for its core business and underscores our strong market position in China. It shows how local production, technological excellence, and international cooperation lead to global success. We will continue on this path – with innovation, a strong customer focus, and local responsibility for implementation,” said Jürgen Otto, CEO of Heidelberg, in his welcoming remarks during the anniversary celebrations.

Michael Nilges, head of the Shanghai site, added, “The success story of the Heidelberg Shanghai site is closely linked to the commitment of its employees. The culture is performance-oriented and pragmatic, with a family-like cohesion. The cooperation between German and Chinese teams is living proof of our company’s intercultural strength.”

China – growth driver for the entire company

The Chinese printing market is a growth driver of global relevance for Heidelberg and also the largest single market for printing presses worldwide. Initially, machines in standard configurations were manufactured at the Shanghai site, primarily for the Chinese market. However, rising demand and the plant’s growing experience resulted in the site also playing an increasingly important role for more complex models and international markets.

In China itself, packaging printing is developing particularly dynamically. Packaging and labels account for almost 50 percent of the Chinese printing industry, and the market for folding cartons is growing particularly by around three percent annually. Some 75 percent of Heidelberg customers in China come from the packaging segment, and the company has a market share of around 50 percent in the Chinese market for modern sheetfed offset systems. Speedmaster XL technology manufactured in Germany is helping to meet this demand. Commercial printing, too, remains an important market for Heidelberg in China, especially for smaller print runs and customized applications. In this segment as a whole, demand for flexible, highly productive, and cost-efficient solutions in conjunction with digital printing technologies is also increasing in China.

“The machines manufactured by Heidelberg in Shanghai are in no way inferior to those from company headquarters in Wiesloch-Walldorf in terms of quality and efficiency, because ‘Made by Heidelberg’ is a global promise of quality that applies to all our products and locations – a promise that our customers worldwide can rely on,” emphasized Otto.

Milestones from two decades at the Heidelberg Shanghai site

2005: Groundbreaking ceremony for the new Heidelberg site in Qingpu, near Shanghai – Heidelberg is the first German printing press manufacturer to venture into building its own plant in China.

2006: Start of production, with folding machines and the Speedmaster SM 52 and SM 74 printing presses for small and medium formats.

2007–2011: Expansion with two additional buildings, including a 21,500-square-meter assembly shop for the Speedmaster CD 102.

2013: Delivery of the 1,000th printing press – a milestone for the plant and a symbol of “Made by Heidelberg in Shanghai” quality.

2014: ISO 9001 and ISO 14001 certification – confirmation of the highest quality standards.

2015: Opening of the Print Media Center (PMC) Shanghai – a training and demonstration center for customers from all over Asia.

2021: Start of production of the Speedmaster CX 104, which was unveiled at the China Print trade show in the same year.

2024/25: Record year, with around 1,500 printing units assembled and an export quota of 40%, 21% to markets outside Asia.

2025: Modernization of the Print Media Center Shanghai based on the model and style of the “Home of Print” at company headquarters in Wiesloch-Walldorf – over 350 international customers visit the new center. To date, a total of over 16,000 printing and coating units and almost 3,300 printing presses have been delivered from the Shanghai plant.