A press release dated 2 December 2020 reveals that Heidelberg is strengthening its partnership with Tianjin China based converting equipment manufacturer Masterwork. The two companies have expanded their strategic cooperation by setting up a production joint venture at Masterwork’s 328-acre site in Tianjin. The new automated plant is to contain an intelligent printing equipment production line.

The two companies also expect to expand their strategic cooperation through joint parts production by the joint venture to open up substantial opportunities for boosting efficiency, particularly at Heidelberg’s production site in Qingpu, about an hour from Shanghai. “The manufacturing joint venture with Masterwork is a further milestone in the successful cooperation between the two companies and opens up additional opportunities for Heidelberg in China,” said Rainer Hundsdörfer, CEO of Heidelberg.

“With a sales volume of around Euro 300 million, China is Heidelberg’s most important single market in the graphic arts industry. We have increasingly strengthened our leading market position by expanding our range of products at our production site near Shanghai. The increasing purchase of locally manufactured parts will significantly increase our competitiveness in this growth market.”

Under the terms of the cooperation agreement, the joint venture will take over some of the machine parts previously manufactured by Heidelberg. The main customers are the Heidelberg Graphics Equipment plant in Qingpu (Shanghai) and Masterwork and its affiliated companies. Production is scheduled to start at Masterwork’s new Tianjin site at the beginning of 2021.

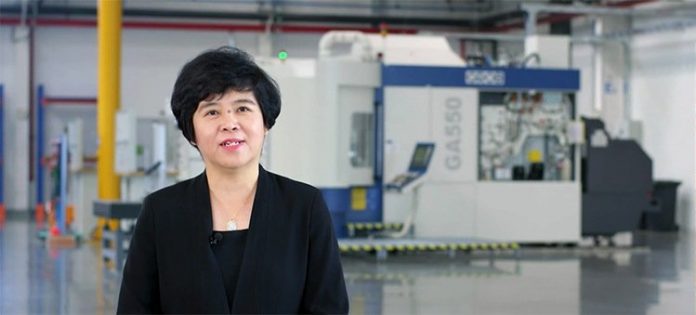

“The joint venture between MK and Heidelberg is a very important step in both sides’ strategic development. Our common goal is to provide high-quality, cost-effective, and intelligent products for the market to better meet and service customer needs,” says Masterwork president Li Li. “Through this cooperation, the joint venture will introduce the most advanced management, production, and manufacturing technologies, all of which are based on Industry 4.0. In addition, various processing centers representing the world’s most advanced level will also be put into use in the joint venture to ensure the best performance and maintain the same high-quality standards as Heidelberg. We firmly believe that the joint venture will live up to the expectations, especially the quality requirements. Finally, we are very happy with this cooperation. By learning from Heidelberg, Masterwork will surely upgrade to a new and higher level of manufacturing and production skills worldwide.”

Around 900 Heidelberg employees work in China, of which 450 are in sales and service. This puts Heidelberg in an excellent position to take advantage of growth opportunities in China and Asia in the future and to further develop and secure these markets for Heidelberg. Two branches in Beijing and Hong Kong and three offices in Guangzhou, Shanghai, and Shenzhen ensure comprehensive customer support on-site.

Aiming for the packaging printing market

Together with Masterwork, China’s largest manufacturer of die cutters and hot foil embossing presses and a long-standing sales partner, Heidelberg also aims to significantly expand its market position in the growing packaging printing sector. At the Qingpu factory, Heidelberg has expanded the manufacture of its SM and CD machines by gradually making longer and more complex machines. The newly designed, slightly smaller than B1 CS presses, are made only in Qingpu and have been a success with commercial printers in Asia and worldwide.

The alliance between the companies in 2014 started with Heidelberg marketing Masterwork’s die-cutters, and there was some transfer of know-how from Heidelberg on converting equipment including folder-gluers. Even then, there was a provision to extend the joint venture on finishing equipment into parts and press production. In early 2019, Masterwork obtained 8.5% of Heidelberg shares after its capital increase decided by its board in March 2019. Masterwork, as a strategic anchor shareholder, owns approximately 8.5% of Heidelberg shares, a figure similar to that of its other anchor investor Ferdinand Reuesch – making them the two anchor shareholders in the company.