At interpack 2017, Bosch Packaging Technology will present the new KLV series for Container Closure Integrity Testing (CCIT). “In the pharmaceutical industry, non destructive CCI technologies are becoming increasingly important,” explains Jérôme Freissmuth, product group head at Bosch Packaging Technology. “Even the smallest leaks can be highly hazardous for patients. The active ingredient could alter, and administering the medication could lead to serious side effects as a result of non-sterility, or the medication could become ineffective. Furthermore, non-destructive integrity testing protects pharmaceutical manufacturers against the loss of valuable medication, since the container remains intact during testing.”

Bosch has continuously expanded its portfolio of CCI technologies in recent years. High voltage leak detection and laser-based headspace analysis are now complemented by the new KLV series for vacuum leak detection. Wolfram Schindler, engineer measurement technology at Bosch Packaging Technology says, “A special feature is the combination of testing sensitivity and high output.”

In vacuum leak detection, negative pressure is created in hermetically sealed chambers. If the container is faulty, the leaking fluid or gas causes the pressure to rise. The KLV 1360 measures this pressure increase with very high sensitivity. Thanks to state-of-the-art measuring technology, the machine is able to measure leaks equivalent to hole sizes of less than five micrometers.

The KLV ensures a consistently high inspection quality. It is the first machine of its kind where the integrated robotic system not only feeds the containers that require inspection into the process. It also adds reference samples for internal process control. In addition, automatic re-inspection makes sure that only containers, which have clearly been tested, leave the machine. Even after inspection, the product and closure quality remain a top priority.

The KLV does not grip the containers from above. Instead, the slightly slanted transport system makes it possible to remove the conatiners from the inspection chamber sideways in order to prevent leaks occurring due to closure gripping. Furthermore, a star-wheel system ensures gentle transportation through the system with minimal wear and tear. Thanks to its modular construction, the KLV 1360, which has a turntable fitted as standard, can be seamlessly integrated into existing lines.

The KLV does not grip the containers from above. Instead, the slightly slanted transport system makes it possible to remove the conatiners from the inspection chamber sideways in order to prevent leaks occurring due to closure gripping. Furthermore, a star-wheel system ensures gentle transportation through the system with minimal wear and tear. Thanks to its modular construction, the KLV 1360, which has a turntable fitted as standard, can be seamlessly integrated into existing lines.

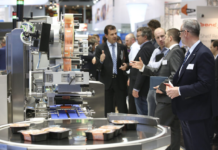

The new KLV 1360 completes Bosch’s inspection portfolio. Visitors to interpack can learn about the entire range of technologies – from visual inspection and headspace analysis to vacuum testing, all of which will be showcased as benchtop models. “Our customers not only have a wide choice of technologies,” Schindler underlines. “We also advise them on the best inspection solutions for their liquid or lyophilized medications and are their experienced partners when it comes to regulatory requirements and individual solutions.”