Emsur, Karlville, SK microworks and Siegwerk have join forces to carry out the #SleeveConnect project in shrink sleeve technology. This initiative showcases the synergy achieved through the collaboration of four industry giants: Emsur, a leader in flexible packaging; Karlville, which offers cutting-edge machinery; Siegwerk, a provider of customized inks and coatings; and SK microworks, a prominent name in the film industry. Together, they have given rise to an ingenious packaging solution that not only facilitates bottle designs but also champions environmental sustainability.

The washable inks of the rPET bottle’s c-pet sleeve make it an easily recyclable monomaterial that can also incorporate innovations in the recycling process, such as a digital watermark that allows for accurate detection during sorting.

The bottle produced by the innovative start up ‘BTC Concept’ has a high-quality shelf impact due to the high opacity white sleeve which gives more visual ‘body’ to the design and enables a non-colored bottle to give both high quality shelf impact whilst being 100% recycling friendly under the correct reprocessing conditions. The different finishes, such as Soft Touch or Matt Effect, make the product even more attractive and demonstrate the endless possibilities when printing the sleeve.

Uncolored bottles will be a good source of high quality recyclate for the future and this sleeve solution is the ideal complement for any type of transparent bottle. The production process is realized on the Karlville machines after the sleeve has been processed in Emsur with washable inks and coatings from Siegwerk and C-Pet shrink film from SK microworks.

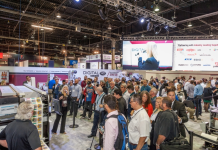

The #SleeveConnect project will be launched at the trade fair Labelexpo Europe. From 11 to 14 September, at Karlville’s stand, the production process of these innovative sustainable bottles will be on show.