At Labelexpo India, Capital Graphic Supplies/Tresu Group plans to showcase ancillary equipment, including supply systems and chamber doctor blades for controlling and automating ink coating supply in narrow- and mid-web flexo printing presses.

Tresu’s flexo ancillary solutions provide enclosed, automatically controlled ink circulation, thus reducing make-ready time and material waste, and assuring uniform quality. The F10 iCon ink supply system regulates ink flow, pressure and viscosity, ensuring a constant, accurate ink density on the printed substrate, without air contamination. This energy-efficient system also provides thorough automatic cleaning, achieving a complete ink change cycle in 5 to 10 minutes.

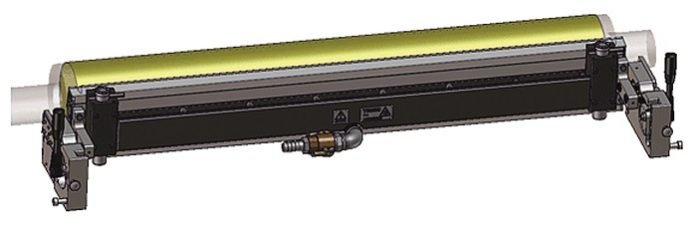

Tresu’s chamber doctor blades offer many benefits to label and packaging printers, including reduced ink and substrate waste, uniform print quality, increased press speeds, shorter cleaning times and reduced emissions. Featuring the company’s patented seal system, they prevent leakage and air contamination, thereby ensuring clean, blister-free print result with fast drying characteristics, better reflection and higher gloss values. When doctor blades need replacing, Tresu’s patented clamping systems enable changeovers in less than 2 minutes.

Exhibited chambered doctor blade systems include the FlexiPrint IMW E-Line, for widths up to 1800 mm (70.8 in) and speeds up to 500 m/min (1640 ft/min); and the closed-cassette FlexiPrint Reservoir, which needs no pump and operates at press speeds of up to 300 m/min (984 ft/min).

Tresu’s lightweight carbon fibre chamber doctor blades up to 6,000 mm (236 in) width feature a top-coated ink-repellent surface, offering protection against detergents and adhesives with pH values of 9.0 and above, and easy cleaning. Curved inner surfaces maximize volume and facilitate controlled discharge.