Ahmedabad-headquartered Vishakha Polyfab has undergone significant expansion since the beginning of 2020. It has installed a 9-layer blown film line and a sophisticated gravure press and pouch making machines at a just-commissioned new plant in Kolkata. With the start-up of production in end-November, early December, the plant gives Vishakha enormous close-to-customer capacity, with plants in both Western and Eastern India.

Vishakha is one of the largest high-barrier coextruded flexible film manufacturers in India with its factory premises are spread over 99,000 square meters and a production capacity of over 27,000 metric tons. With its national and international accreditations, BRC & ISO certification, Vishakha’s clients number amongst the leading brand owners in India and across the world. It is an exporter of flexible packaging materials to customers in North and South America, Europe, Australia, Middle East, Asia, and Africa.

India’s first Brampton Aqua-Frost 7-layer film line

It has also expanded the Ahmedabad plant with the installation of the water-quenched Aqua-Frost new Brampton Engineering 7-layer blown film line signed at the last K exhibition in October 2019. The Ahmedabad plant has also added a new gravure press, a laminator, and pouch making machines.

BE’s AquaFrost line, which uses water-quenching technology in the extrusion process, is the system of choice for manufacturers seeking the advantages of cast and conventional blown films. It provides high barrier films with improved clarity and thermoformability, balance orientation, and increased flexibility while consuming less resin.

Leadership in high-barrier films

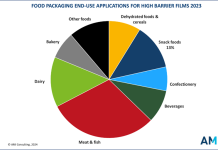

The commissioning of the new blown film and other investments have enhanced Vishakha’s leadership position in the high barrier packaging in India and abroad. Overall, Vishakha’s capacity has been increased by 25%, making it the largest manufacturer of high barrier films using nylon and EVOH in India.

BE and Vishakha Polyfab have been partners for almost 20 years, with Vishakha purchasing India’s first BE 7 and 9-layer multi-layer barrier blown film line not too long ago. “Our close and productive collaboration has enabled us to grow together in the region, and we are looking forward to Vishakha’s continued success in leading the multi-layer barrier blown film industry in the region.”

Significant confidence and in-house engineering expertise

Vishakha Polyfab was closed for only seven days after the Covid-19 pandemic hit India and the ensuing country-wide lockdown declared on 23 March 2020. Remarkably the company kept to its expansion plans, including setting up the new plant in Kolkata. As the government lifted the lockdown, the company’s engineers installed the new imported equipment.

The expansion has added two gravure presses, two blown film lines, a laminator, and five pouch making lines. Since overseas engineers couldn’t travel to India, the installation and commissioning of the new equipment have been performed by the company’s engineering teams with remote video and guidance from the manufacturers’ engineers.

Growth driven by India’s packaging sector has established the country as one of the most sought after barrier film manufacturing markets globally. The country is among the three largest global markets, and barrier film manufacturers have gravitated towards BE’s innovative technology. Known for its pioneering technology, the company has the distinction of being the first to deliver complete 8, 9, 10, and 11-layer blown film systems in air-blown and water-quenched lines. From die technology, water-quenched technology, 11-layer film, and more, BE’s patented cutting edge technology, and commitment to innovative solutions has enabled its partners in barrier packaging to produce a full range of high-performance blown films all over the world.