Welbound, a leader in the Indian postpress solutions space, forayed into the packaging space about three years ago. In 2015, the company introduced the HC 500, a top and bottom case sealer for end-of-the-line packaging. The idea behind developing this solution was to cater to a segment of packaging which has been facing severe issues of pilferage and damages.

For the last one year or so, Welbound has been testing the case sealer on site at multiple customer locations across a range of industries. “This concept is new for the industry where sealing with tapes is the norm. However, these tests have helped us get close to the actual players in the industry. We now understand what opportunities we have, the challenges we face, what we need to do and what kind of partnership we need,” says P Sajith, marketing director, Welbound.

For the last one year or so, Welbound has been testing the case sealer on site at multiple customer locations across a range of industries. “This concept is new for the industry where sealing with tapes is the norm. However, these tests have helped us get close to the actual players in the industry. We now understand what opportunities we have, the challenges we face, what we need to do and what kind of partnership we need,” says P Sajith, marketing director, Welbound.

Sajith believes the Indian market holds tremendous potential when it comes to roviding the right solution for the huge issues related to transit security. There is a growing need to protect the products from shipper to shelf, he says. “Brands have begun to recognize this constraint.” There are numerous advantages of replacing tapes with glue for shipping cartons: superior tamper proofing due to visibility of fiber tear, structural rigidity as all flaps are glued together, low downtime as gluing is faster, lower long-term operation costs, long-term storage and shipping and sustainability improvement in hotmelt versus tapes to name a few.

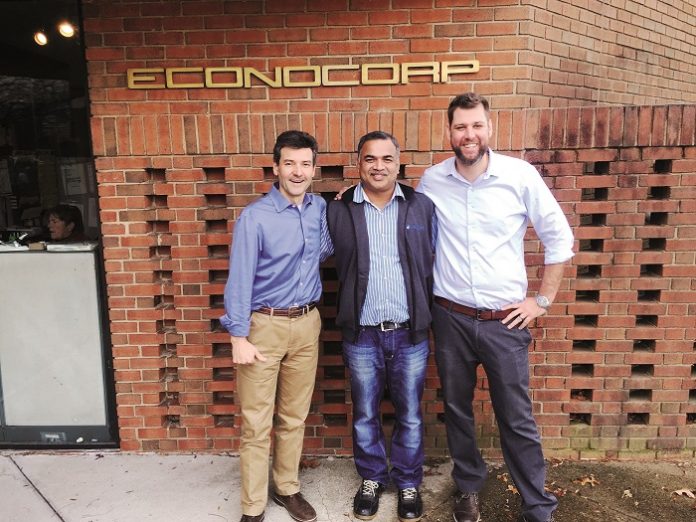

Sensing the huge potential of growth in end-of-the-line packaging, Impel Services Pvt Ltd, the packaging segment initiator of Welbound group, will partner with US-based manufacturer of end-of-the-line equipment Econocorp Inc. for joint activities in South Asia. Econocorp manufactures case packing, tray forming and cartoning equipment. Econocorp is a half-a-century-old organization based in Randolph, MA. Welbound’s chief technical officer Suresh Nair was in the US recently to absorb the details of a varied range of products that find application in end-of-the-line automation across different industries. “We found a high level of synergy with them. In South Asia we will take care of sales and services. We will leverage our close to 100 people strong sales and service team to spread the benefits of the Econocorp solutions across the country. We will also use our marketing channels to discuss the benefits in automating the case packing, wrapping and also for seeking security of products in transit,” says Sajith.

Welbound has been working closely with OEM partner, Nordson for gluing systems

and has now joined hands with SIAT of Italy for specialized taping solutions.

interpack 2017

The company will be participating in interpack 2017 for the first time as an exhibitor. It plans to work in close coordination with its partners including Econocorp in promoting practices for improving product protection and security in shipping. Welbound’s packaging division has a specialized sales team and the product range has been given a unique brand name, STELDA, which is the short form for Security Tamper Evidence Low Damages in Transit. At interpack, there will be on display STELDA random case sealer AR500GT with multiple sealing options. The model AR500 GT supports hotmelt glue, dispersion adhesive (WBA) and adhesive tapes. Before entry into the machine, each box is measured and every setting is automatically changed to seal the box perfectly. The machine also has an On-Demand-Case Sealing (ODCS) feature that provides huge flexibility to brands for manufacturing, where the market demands multiple SKUs. Every box that can be sealed by the AR500 can be a different size—be it length, width or height.

The multiple sealing options—of adhesives or tapes—allow contract packagers to switch between the preferred options without moving into another line or machine. The solution also supports taping after gluing as an additional security measure. AR500 GT will be displayed at interpack 2017 with IIOT support (Industrial Internet of Things), which means users will be able to access realtime production data even while they are on the move.