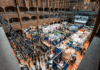

At the inaugural Packaging Design Innovation Technology (PDIT) conference held in Mumbai and organized jointly by IPPStar and Messe Dusseldorf India, stakeholders from the consumer product, food and packaging industries deliberated on key technologies that can help avoid food wastage. Debabrata Deb of Future Formats made a detailed technology presentation on how active and intelligent packaging plays a critical role in reducing food wastage. He said, Active packaging is an integral part of not just food-grade packaging but also pharmaceutical and other perishable consumer products in distribution, retail, food service and home consumption.

In the PDIT Conference in Mumbai in December 2016, Deb spoke about the many factors that cause food deterioration such as microbiological, enzymatic and biochemical compounds, and why it needs to be processed to control and minimize such deterioration over the product’s life till consumption. “Active packaging is designed to deliberately interact with the food and its environment after packaging and it works when two key requirements are met—the packaging should have suitable barrier properties and the pack seal is hermetic. The other aspects of active food packaging design include headspace conditions (RH, oxygen, microbial load), storage temperature, the incidence of light and UV, and atmospheric humidity,” explained Deb.

He pointed out that moisture regulation in active packaging is achieved through salts that balance the moisture in the product, whereas anti-microbials prevent the growth of micro-organisms in the form of fungi and bacteria in the food. The most important active packaging component is oxygen scavengers as 70% of all active packaging is driven by oxygen scavengers, which have the largest commercial application, such as sachets of reduced iron oxygen scavengers inserted inside the pack. “All oxygen scavengers are anti-oxidants and typically intercept, absorb and scavenge to reduce oxygen levels in the food,” he went on to say.

Intelligent packaging

Deb also took up intelligent packaging, about which he said, “Intelligent packaging interacts with the interior and exterior of a pack and informs the consumer about the product, especially if it is fit for consumption. It informs stakeholders in the supply chain about the product’s history and uses sensors and signals to monitor and display the pack’s interior and exterior states.” Intelligent packaging reassures consumers on the fitness of the product with suitable signals and helps better monitoring of the supply chain whereby damaged, deteriorated or pilfered products can be detected.

Deb also took up intelligent packaging, about which he said, “Intelligent packaging interacts with the interior and exterior of a pack and informs the consumer about the product, especially if it is fit for consumption. It informs stakeholders in the supply chain about the product’s history and uses sensors and signals to monitor and display the pack’s interior and exterior states.” Intelligent packaging reassures consumers on the fitness of the product with suitable signals and helps better monitoring of the supply chain whereby damaged, deteriorated or pilfered products can be detected.

Intelligent packaging adopts diagnostic and communicating technologies to gauge the product’s fitness for consumption, explained Deb. It uses diagnostic technologies like Time Temperature Indicators (TTI), thermochromic and electroluminescent inks, ‘Done-ness’ indicators as well as indicators that detect freshness, moisture, alcohol, protein and damage, he added. He went on to explain that intelligent packaging uses communication technologies such as Radio Frequency Identification (RFID), Electronic Article Surveillance (EAS) implemented through electronic tags, electromagnetic identification and optics /optoelectronics.

In conclusion, Deb maintained that brand owners and packaging technologists and converters must ensure regulatory compliance. It is important to get

agreement across consumers and regulators on standards and rules which may

require extensive research to ascertain their acceptance. Is a consumer willing

to accept a sachet inside the food pack or the taste of what is claimed as ‘fresh’?

Consumer comfort and preferences while interacting with a pack, as well as

views on food safety and the costs are equally key factors in improving the food

supply chain using technology.