Mukul Luthra, the managing director of Artize Die Makers, did his Masters in Economics from the University of Glasgow in the UK. After completing his studies, he came back to India in 2008. In 2009, he began working for National Council of Applied Economic Research, a government organization. It was at this time, one of his friends in the printing and packaging industry suggested a venture in the die-making industry.

When Luthra began his career, the packaging industry was at a CAGR of 16%, higher than real estate above inflation. An extensive background in economic research made him realize that only 35% of the Indian population had access to packaged goods and it was this demographic that displayed faster growth, solidifying his interest in die-making.

In the past decade, India has registered a massive boom in online retail which has resulted in the eCommerce vertical poised to become a US$ 120 billion industry. The period from 2009-2019 has seen a shift in the retail landscape of India with a number of brick-and-mortar retail set-ups closing down.

Growth of eCommerce helps packaging

This growth has supplemented the demand for packaged goods more than ever as doorstep delivery of goods from seller to end consumer has become a matter of habit. According to Luthra, this clearly points to bullish growth trends in the packaging sector for at least the next two decades.

“If we talk about commercial printers, they’re clearly struggling because of eCommerce growth. As one may observe, many commercial printers have migrated to packaging because they know that the business is going to go down with the rise in the online sector,” Luthra explains.

“From now on, the commercial printing industry is going to be divided into two parts where one will be digitally shot and digitally run customized jobs with print runs as small as 200 to 500 copies of products such as catalogs or books. The other would be high volume jobs such as the packaging printing converters for the FMCG sector. India’s commercial printing industry is expected to see a downturn with commercial printers either having to migrate to a digital set-up or packaging in the long run,” he adds.

In order to understand the die-making industry, Luthra spent time understanding the die-making process. He visited printers and converters to learn the process and the dynamics of this segment of the packaging business and contacted the local manual die-makers who were relatively fewer in number. He received training from various overseas machine suppliers and trained his workforce before launching the business in a full-fledged manner. Finally, in February 2011, Luthra began his die-making business.

Products offered by Artize

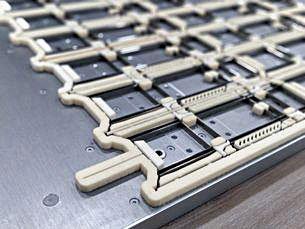

Artize has registered annual growth rates between 20% and 50%, ever since its first year of business. In FY 2018-19, Artize registered 26% growth. Luthra started his plant with a laser cutting machine and a bending machine. With time, he added three more tabletop bending machines and also invested in growing skilled manpower. In 2015, the company moved to a new plant in Kundli (NCR) in Haryana, and added several new machines from Germany, Italy, Korea, China and the UK. Increased capacity also led to the increase in new products such as pertinex counter plate, steel counter plate, embossing blocks and rubberized dies along with basic cutting dies. Artize also added a few products that add value to the existing dies and saves make-ready time for converters.

The forward integration of the Artize plant in Kundli has improved the efficiency of existing dies and saves a lot of operating costs and time, for example cutting dies including nicked rules and rubberizing, male and female stripping dies, embossing blocks, and combination dies with embossing blocks with which the converters can cut, crease, emboss and perforate cartons in a single pass.

Artize has developed a product for embossing and foil stamping in a single pass. For hot foil stamping, the company has launched its easy fix plate, one on which foiling blocks are pre-mounted. It saves make-ready time and wastage of sheets and foil on the automatic foiling machines. It takes less than 15 minutes to set up a repeat job. Artize also makes pertinex counter plate and steel counter plate for creasing, which are higher end substitutes for creasing matrices. Milled steel plate is a high-end solution for creasing, obtained by milling a 1-mm steel plate for high quality creasing, which can run smoothly on autocartonator machines.

“A steel milled counter plate is a very handy solution for long run jobs such as cigarette cartons and for FMCG cartons run on high speed machines or on the auto carbonator machines. To make sure that their auto carbonator machines run at the highest speed, the creasing needs to be perfect because the robot/machine only understands one language, that is, the set pressure. One must have consistency in the creases. Thus, for jobs which are packaged at nearly 800 cartons a minute, these products are extremely handy to make sure production efficiency is achieved,” explains Luthra.

A new product called the sandwich die is related to long-run jobs in which multiple layers of metal reinforced together provide increased stability and consistency. The same die can be re-knifed for more than 20 times.

Artize’s focus on Indian market

Artize has not yet looked at exports. It feels that there is a huge unmet demand in India and supplying to this market is its prime agenda. Although the company has a pan-India reach for specialized products, it finds maximum demand from the North because it feels that dies are time-oriented and need to be logistically viable products, which is not easy in all the far-away regions of a large country.

“Also, if we need to supply a die within hours, the cost of the die increases. The customer always prefers to contact a diemaker who is close by. Nevertheless, we cater to the Western and Eastern regions as well. So far so good, we have a lot of expectations from 2019-20. We are aiming to grow at 35% this time,” Luthra concludes.