“The construction work of the new aseptic packaging plant in Sanand has already started, the machines have been ordered and we are leaving no stone unturned to make sure it is a very high technology, sophisticated and state-of-the art plant for liquid packaging,” says Ashwani Kumar Sharma, president and CEO, liquid packaging and new businesses of Uflex. The company will invest ` 1,500 crore over the next four to five years in setting up the new plant in Sanand and in the first phase of this greenfield expansion, the company is investing about ` 580 crore. “The Indian liquid packaging market is huge and the potential is massive with last year’s growth being 20%. We foresee that this growth will continue for another five years or more. The Indian market is likely to double from 8 billion to 16 billion packs in the coming four to five years while the China market has already touched around 80 billion packs,” he says.

According to Sharma, the Sanand plant will produce 7 billion packs a year for liquid products such as energy drinks, milk and juices, and about 90% of the output will be used for the domestic market. “Our actual full-fledged sales of liquid packaging will start in FY 2017-18. And at the peak capacity we expect to earn an annual revenue of ` 1,200 crore (US$ 185 million) from the Sanand plant. According to Sharma, Uflex also plans to set up facilities to manufacture waterproof cement bags and tubes at the Sanand greenfield site.

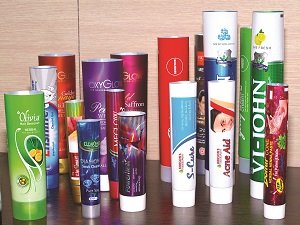

Anti-counterfeit tubes

The tube business in India and globally is a very exciting market because consumers are maturing – especially in the emerging market they are following the trends of more established or what is called mature markets. Moreover, many types of value additions have taken place in the tube industry and more innovation is possible. According to Sharma, the size of the Indian tube market is around 570 million tubes on a monthly basis of which around 53% would be dental care, 26 to 27% would be beauty care, around 18% would be pharma and 2% others.

“In the tube business we are not looking at the low-end dental care market –but we may look at the sensitive toothpaste tubes which are high-end – perhaps we will be entering that market soon. Right now we are extremely focussed on tubes for the beauty care segment,” says Sharma. He goes on to add that India has two major problems in the tube industry and by and large in any fast moving consumer goods (FMCG) industry. First, the quality and cost of local tubes which either kill the brand or erode the bottom-line of big brands; and second, rampant counterfeiting. “In the tubes that we produce, we not only upgrade and give a very sophisticated, aesthetic and premium look to the product, but also make it an anti-counterfeiting packaging – this is the biggest USP of our tubes.”

“We don’t want to work with our clients like the usual suppliers who take design and develop and deliver it – in fact, we always understand customers’ requirements, come up with various options as a strategy and present these to our customers, allowing them to decide the one which would make more sense to them,” says Sharma.

Uflex to launch SafePack – shower-proof cement bags

The cement industry in India is the second largest in the world and has been facing a chronic problem of moisture entering into the bags due to which the product deteriorates during transportation and storage. An estimated 3% of the cement produced is lost in the supply chain due to moisture and associated lump formation. To address these issues, Uflex has designed shower-proof bags to provide a barrier to moisture and water from entering into the bag, helping the cement with stand harsh environments and maintain its full functionality over an extended period of shelf-life. “Uflex SafePack is not just aesthetically beautiful where brands can announce their arrival and connect with their consumers, but includes a very important feature of it being shower-proof and moisture-proof. We are yet to launch these bags in the market but the paradigm shift has already happened in how we have changed the game of cement packaging and its variants [wall putty, white cement and grey cement],” says Sharma.