Tokyo-based Komori Corporation has recently set a new record in sale of its H-UV innovative curing system. Komori’s president Satoshi Mochida says that until now, the company has received more than 1,000 orders for the product. The Komori H-UV system is an innovative UV curing system that uses a UV lamp/LED module developed with Komori know-how and high-sensitivity UV ink. With just one lamp/LED module mounted in the delivery, this system offers high print quality and reliability as well as excellent economic and eco-friendly performance.

The H-UV system has proved to be a successful product of Komori since its release in 2009. In 2011, it was honored with a technology award by the Japanese Society of Printing Science and Technology (JSPST). It was awarded as a technology that has made an outstanding contribution to the growth of the printing industry or to the development of applications for other fields. It also received the 2011 InterTech Technology Award that honors the development of technologies predicted to have a major impact on the graphic arts and related industries.

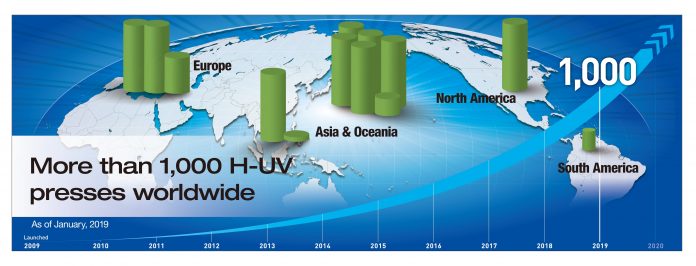

As of January 2019, orders for H-UV system in the 10 years since launch have totaled 1,002 presses, including 527 in Japan and 475 abroad. The H-UV system enables immediate postpress processing and high added value printing on special substrates or package printing due to its instant curing performance. Following the rapid change in the printing industry in recent years of more short runs of many different items and quick turnarounds, it has gained a brand reputation as Komori is getting repeat orders from customers who have already installed the H-UV system.

Mochida says, Komori total support helps maintain high print quality, reduces common problems and lowers costs since all K-Supply brand consumables for the H-UV system are supplied by Komori. It includes the K-Supply H-UV Ink that is the ideal Komori standard ink. For quality control, the effect of changes in materials tends to be temporary. Komori uses its know-how as a press manufacturer to ensure quality control by not only supplying materials but also through recommending and providing machine maintenance.