Prinect Package Designer is the CAD software for making carton design and die-lines. The Package Designer module has a library of designs from ECMA and FFECO. The software enables connection to any cutting and creasing sample making machine for prototyping. A 3D view of the carton can also be exported from Package Designer. The functionality ranges from structural design through sample production, sheet layout and die-cutting parameterization to the generation of presetting data for postpress. The 3D display and animated folding sequences make it much easier to coordinate with customers and graphic designers. And it can help to set up the folder-gluer faster and more accurately.

Once the carton is designed and the multi-up step and repeat layout is created, it can be exported as a CFF2 file, which can also be used by the die-maker. The Diemaker option enables the drawing of die-cutting forms with bridges, cut-off and compensating knives. The die-cut information can be forwarded to the die-cut tool maker or can be used for the control of machine tools.

In parallel, the Prinect Signa Station Packaging Pro also imports this CFF2 file (which is a multi-layout CAD already) on a plate template. Once this is done, the one up content PDF is positioned on the CFF2 file with a drag and drop functionality. So the multi-layout CAD file acts basically as a place holder for the one up content pdf. A one-up key line created in Corel or other software can also be directly imported into Prinect Signa Station Packaging Pro to create a step and repeat layout with interlocking in the Signa Station itself. The automated creation of layouts for different printing formats is done quickly with the automatic and interactive positioning of all marks and control elements.

Trapping in Prinect PDF Toolbox

Trapping is either done using the Prinect PDF Toolbox (which is an Acrobat Plugin) tool called the Trap Editor with a click of the mouse or can be automated using the PDF Automation Pack in the workflow which starts with Prinect Prepress Manager.

Apart from trapping, PDF Toolbox has other functionalities such as preflighting files and generating a PDF Report Generation, Color Editor, Bar Code Editor, Coating Editor, and Object Editor. PDF Geometry settings such as Trim Box, Bleed, Scaling, and Rotating are also done using the tool called PDF Assistant.

The Prinect Prepress Manager module contains tools such as the Prinect Renderer (will all types of Screening options (AM, FM, Hybrid, Object Screening) and CIP4 Generation. The Prinect Renderer can also write to a Color Proofer through the Color Proof Pro Option. Heidelberg’s Screening System and Press Calibration tools are part of this module.

The Prepress Workflow module can be extended up to the printing press using the Prinect Pressroom Manager, which helps to reduce the makeready of the press, by giving the right data to the press by way of job information and ink presetting. The information includes job ID, job name, paper size, paper thickness, color information, ink data, run-length, ink-presetting data and other helpful parameters.

Horizontal and vertical integration with postpress and MIS systems

The Prepress Manager and Pressroom Manager modules talk to each other with a Prinect Integration Manager layer on top of both. This architecture enables a packaging printer and converter to expand the workflow horizontally to include a Prinect Postpress Manager as well. Vertical integration is also possible with a JDF compatible MIS software and W2P connectivity.

The workflow module contains a database called the Analyze Point, which can deliver job data, shift data and productivity information, all of which help to calculate the Optimal Equipment Efficiency (OEE) in real time.

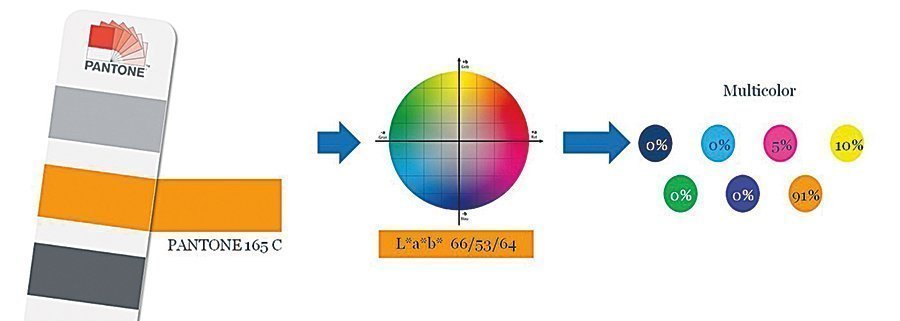

Multicolor

Heidelberg’s integrated workflow containing these key packaging modules helps carton converters implement its new technologies such as Multi Color that are used for extended gamut printing which reduce the need for many of the special and brand color inks and wash-ups on a 6-, 7- or 8-color press. Multicolor technology is claimed to cover up to 95% of the Pantone color space using the CMYK Multicolor process colors plus orange, green and violet inks. Multicolor is already being implemented by at least a couple of Indian packaging printer converters.

Ashokan K, general manager Prepress of Heidelberg India says, “Multicolor is already being implemented by at least a couple of Indian packaging printer-converters. In fact, Heidelberg’s ‘Push to Stop’ technology on the press can be implemented perfectly if the print shop’s workflow is complemented with Prinect modules.”