Vasai-based Saroj Art Prints operates from its 20,000 square foot plant spread over three floors. It manufactures mono cartons primarily for the pharmaceutical industry and has a capacity to produce on average 5 lakh cartons per day.

At present it has three Heidelberg offset presses on its shop floor: one 4-color, one 2-color and one single color press of size 20 x 28 inches. It has also a fully equipped quality control laboratory as well as a complete prepress department.

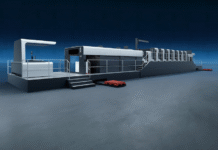

New Bobst Ambition 76

In August 2017, Saroj installed a brand new Bobst Ambition 76 A1 folder gluer to modernize its converting section.

“Earlier, we were doing mostly straight-line cartons and crash-lock bottom cartons were finished manually. However, with time, we experienced gradual increase in volumes of lock bottom cartons at our end and it was not making much sense to continue using manual processes in finishing these types of cartons. That is when we decided to opt for a Bobst Ambition folder gluer,” says Manoj Todi, chief executive officer of Saroj Art Prints.

Now Saroj Art Prints is doing significant volumes of crash-lock bottom cartons and a lot of errors that happened during the manual process have been eliminated.

“We have now gained enough confidence to accept orders without worrying about the quality. We are able to commit the delivery time because we are assured of the quality of our cartons,” shares Todi.

Bobst Ambition 76 folder gluer can produce a range of products like presentation folders, wallets, and brochures, through to CD/DVD sleeves and a wide range of packaging. It can process materials like carton-board with maximum thickness of 0.024 inches and corrugated board with N, F and E flute type. The Ambition 76 folder gluer runs at a speed of 66 to 984 feet per minute (20-300 meter per minute) depending on the substrate to be converted.

Moving beyond pharma

Having catered to the pharmaceutical industry for years, Todi now has plans to diversify into other areas as well. He shares that Saroj Art Prints is looking to serve industries such as food, garments, beverage, FMCG, etc.

“We have been focusing solely on the pharma industry and I feel now it is right time to look at other industries as well. It makes sense to have a diversified customer base,” he says.

With this diversification in mind, Todi plans to invest in two pre-owned Heidelberg presses this year. Saroj Art Prints will invest in a 2-color and 5-color with coater press. It will also invest in a digital sample making machine.

“We have already placed an order for the pre-owned 2-color press from US, which we are expecting by the first week of March. The cutting table will also be installed in the same month. The 5-color with coater press will arrive most likely by Diwali this year,” Todi shares.