Every year, thousands of us are subjected to the most outrageous outfits and accessories strutting down the catwalks of Paris and Rome. The way that we ‘package’ ourselves as people is forever changing − and at an alarming rate. Although possibly not quite as glamorous, the world of processed cheese is also faced with changing attitudes of its own.

Although slightly different than this summer’s latest t-shirt craze, processed cheese packaging is also changing all the time as consumers’ attitudes, tastes and diets evolve. Consumers now demand single slice portions for smaller appetites, foil wrapped triangles for increased convenience and flavoured cheeses for when they’re craving something different. This can lead to manufacturers trying to second guess the next ‘fashion’ trend.

Luckily for processed cheese manufacturers, unlike their fashion counterparts, the latest technologies are able to quickly adapt to meet consumer demands. The range from Sapal, a Bosch Packaging Technology company, for example, opens up a range of flexible packaging solutions, including:

Individually wrapped processed cheese slices (IWS): From as little as 13 grams (the lowest weight on the market) and hermetically sealed, IWS are easy-to-open and prevent re-contamination.

Individually wrapped processed cheese slices (IWS): From as little as 13 grams (the lowest weight on the market) and hermetically sealed, IWS are easy-to-open and prevent re-contamination.

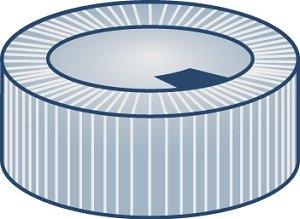

Round portions of spreadable, processed cheese conditioned in aluminum foil: Allowing customized filling, wrapping and packaging options

Round portions of spreadable, processed cheese conditioned in aluminum foil: Allowing customized filling, wrapping and packaging options

Single or twin stack packaging: A secondary packaging process that allows custom amounts of single, twin or triple stacked cheese slices.

Single or twin stack packaging: A secondary packaging process that allows custom amounts of single, twin or triple stacked cheese slices.

A portion of processed cheese wrapped in aluminium foil: High level of product preservation and adaptable shape packaging, that is triangular, square, rectangular or round.

A portion of processed cheese wrapped in aluminium foil: High level of product preservation and adaptable shape packaging, that is triangular, square, rectangular or round.

Square portions of spreadable, processed cheese: Often primarily packaged in aluminum and secondary cardboard, material savings are achieved with perfect symmetrical wrapping

Square portions of spreadable, processed cheese: Often primarily packaged in aluminum and secondary cardboard, material savings are achieved with perfect symmetrical wrapping

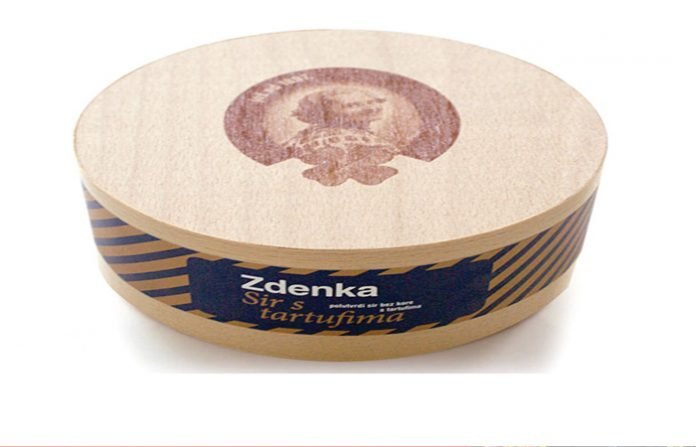

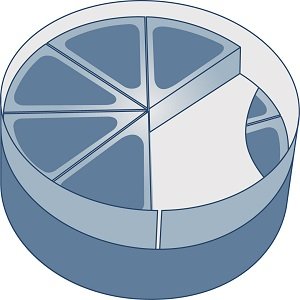

Triangular portions of processed cheese conditioned in round-shaped carton boxes: Enables producers a choice of cardboard packaging including single and multi-layers – allowing for different flavours to be stacked alongside one another.

Triangular portions of processed cheese conditioned in round-shaped carton boxes: Enables producers a choice of cardboard packaging including single and multi-layers – allowing for different flavours to be stacked alongside one another.