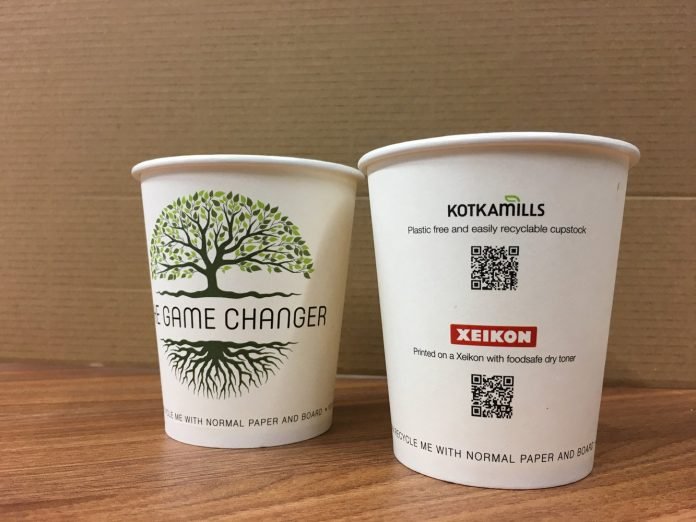

Xeikon has announced its partnership with Kotkamills Oy. Visitors to this year’s Xeikon Café will have the opportunity to see the first demonstrations of the Xeikon 3500 dry toner digital press printing on Kotkamills ISLA Duo paper cup stock. This sustainable and plastic-free food packaging solution carries the potential for paper cup converters to create new business opportunities.

The cooperation validates Kotkamills ISLA Duo paper cup stock as the ideal media for the Xeikon 3500 range using dry toner technology. Xeikon’s digital printing method using food safe dry toner technology together with Kotkamills’ plastic-free, recyclable and biodegradable board produces a digitally printed paper cup that answers consumers’ demands for sustainable paper cups to be used for drinks on the go.

Sébastien Stabel, market segment manager ‒ Carton Packaging at Xeikon, said, “We were delighted to test and validate the new paper cup stock ISLA Duo from Kotkamills. During testing, we saw a match between our food safe dry toner technology and the ISLA Duo board characteristics. We tested printability, productivity, and toner adhesion. The results were excellent and consistent.”

Xeikon printed the Kotkamills ISLA Duo on a roll-to-roll Xeikon 3500 series with dry toner technology. Following the excellent results, Xeikon added the ISLA Duo to its print media list as a Xeikon validated substrate. Stabel continues, “We are convinced that our roll-to-roll dry toner engine set-up offers a perfect technical fit for paper cup converters and has the potential to create new or alternative business opportunities.”

Kotkamills board production technology and the raw materials used in the ISLA Duo production offer a high stiffness cup with a smooth and pleasing tactility. The barrier properties needed for the paper cups are produced with water-based dispersion, making it a plastic-free alternative. Unlike traditional PE coated paper cups, the water-based dispersion barrier layer of the ISLA Duo does not become charged by static electricity. This is the innovative key to achieving high printing speeds and excellent stackability properties.

Saila Kettunen, director ‒ Barrier Boards at Kotkamills Oy said, “The cooperation with Xeikon in developing the high-quality of digital printing of our ISLA Board has been very smooth and fruitful. The suitability of our material for digital printing provides cup producers with the possibility to offer individual and smaller, customized batches of plastic-free paper cups that are easy to recycle within any paper or board waste streams. We consistently endeavor to bring our best know-how and experience to our innovations. At Kotkamills, we are passionate about changing the game, and we are proud to have been nominated as one of the winners of the NextGen Cup Challenge, the global innovation initiative that took place at the end of February 2019. This groundbreaking challenge was launched by the NextGen Consortium dedicated to advancing the design, commercialization, and recovery of food packaging alternatives.”

“By working together with leading suppliers in substrates, workflow, converting, and finishing we effectively demonstrate what can be achieved by fully integrated end-to-end solutions for digital production. At the Xeikon Café 2019, we will share actual applications and business ideas that have proven to immediately drive business growth. We are delighted to be working with Kotkamills as our partner and we are looking forward to piquing the interest of our visitors in this game-changing solution,” concluded Stabel.

For more information about the 2019 Xeikon Café events, visit www.xeikoncafe.com.