To achieve the target of 100% reusable, recyclable or compostable packaging by 2025 is challenging for suppliers. The brand request is causing one of the biggest technological shifts in the industry in recent times. On this issue, Steve Carey, managing director of Bobst Manchester outlines how Bobst offers fully new and sustainable solutions.

Carey says, “Vacuum metallization has the ability to achieve an excellent barrier to oxygen and moisture at extremely thin coating weights compared to conventional wet coating layers. Hence makes it much easier to recycle, which is an important consideration going forward for brand owners.”

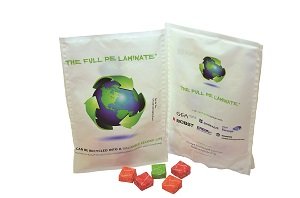

The majority of flexible packages are made up of different materials, which are not compatible to be recycled together so for recycling to take place, the materials need to be separated which is a huge obstacle. So for good environmental sustainability, the target is to move to mono-material substrates.

laminate by Bobst

“The co-operation along the value chain is necessary to work on end to end solutions. In keeping with this, we have recently forged new partnerships across the industry where we have focused our resources and have been participating in a number of initiatives. The search for unified sustainability and recycling solutions for mono-material substrates, co-ordinated by leading packaging experts, was one of them. We knew that achieving this would require collaboration along the value chain.”

Partners working with BOBST on this initiative include Borealis and Borouge (Spain) for resin production, Hosokawa Alpine (Austria) for converting of the raw material into film and GEA (the Netherlands) for the production of the stand-up pouch. As partner, BOBST provided a full solution to prepare the newly created PE film for conversion into the final pouch without damaging the barrier, and assisting in the creation of a fully recyclable mon-material suitable for food packaging, through its Competence Centres in Manchester and Italy.

Carey explains, “In each section of the packaging value chain there is the need to innovate. For us, the challenge really is to improve shelf life by using coatings on lower quality films to improve the barrier properties to that of a higher quality film. This challenge is not only existent in mature markets such as Europe and North America but is also being driven very strongly in emerging markets in particular India.

“The current climate is very challenging for producers of plastic films and as a solutions provider to this industry, we need to continue to innovate in the area of recyclability and sustainability. This means alongside being at the forefront of developing innovative barrier solutions, we are also looking to reduce the amount of material used in the packaging film, a process known as Delayering. Finally going forwards, we additionally wish to consider alternative solutions, which are more environmentally friendly and have a massively diminished carbon footprint.”