Gerresheimer ceremoniously took over a new building in Berlin, Ohio. In the future, the square plastic containers of the Duma Twist-Off Q brand with a 40-milliliter filling volume, child-resistant closure, and desiccant for filling with medications for the North American market will be produced here in a cleanroom. The new building is Gerresheimer’s eighth location in total on American soil and is being built directly next to Gerresheimer’s prescription packaging production facility. A major customer of the company has now audited the site for its orders.

“Many companies around the world produce bottles and closures from plastic. However, very few of them are produced in controlled areas and even fewer in classified cleanrooms like those at Gerresheimer. This is because it is the only way Gerresheimer can guarantee and ensure the quality and purity of the container solution used to package medicines. This is what Gerresheimer offers at each of its primary production sites for plastic packaging around the world. This project is a great example of successful knowledge sharing between the teams in the US and Denmark,” said Niels Düring, global executive vice president Plastic Packaging, who cut the blue ribbon at the dedication ceremony.

In the future, primary plastic packaging of the Duma Twist Off square brand with a 40-milliliter filling volume with a child-resistant closure and desiccant for filling solid medications will be produced at this new production facility in a cleanroom classified to ISO 8 standards.

Produced in a clean room — Duma Twist-Off Q

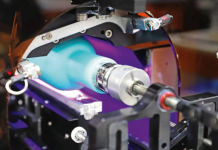

Produced in a cleanroom using injection blow molding, the container is made of HDPE (high density polyethylene) and has a closure made of PP (polypropylene). The Duma Twist-Off square product family consists of seven products with volumes ranging from 30-200 milliliter. All bottles have injection-molded screw systems and are safety-packed. They are available with senior-friendly closures, which can also be supplied with child safety locks as an option. They are available with inserted or integrated desiccant. They can be additionally sealed with the Duma OneLiner closure. The containers have all the necessary approvals, in particular FDA, US and Canada Drug Master File.

As a specialist in plastic packaging solutions for the pharmaceutical industry, Gerresheimer offers a wide range of packaging solutions for solid, liquid and ophthalmic products. The leading brands Duma, Dudek, and Triveni for solid dosage forms, PET bottles of the edp brand for liquid dosage forms, and products for ophthalmic applications are part of the comprehensive and innovative product range.

The broadly diversified standard range includes a wide variety of containers and closures, PET bottles, eye droppers, nasal sprays, nebulizers, applicators, accessories, and countless customer-specific developments.

Gerresheimer is a global partner to the pharma and healthcare industry. With specialty products made of glass and plastic, the company contributes to health and well-being. Gerresheimer is represented worldwide and produces with around 10,000 employees wherever its customers and markets are. With plants in Europe, North and South America and Asia, Gerresheimer generates sales of around Euro 1.4 billion. Its wide range of products includes pharmaceutical packaging and products for the simple and safe administration of medicines – Insulin pens, inhalers, micropumps, prefillable syringes, injection vials, ampoules, bottles and containers for liquid and solid medications with closure and safety systems as well as packaging for the cosmetics industry.