Asahi Photoproducts is celebrating its 45 years of contribution to the label industry and flexographic technology. On this occasion Dr. David Galton, European sales director for Asahi Photoproducts, shared his views on the company’s long growth chart.

Sharing the history of flexographic printing, Galton said, “Forty-five years ago, the narrow web reel-to-reel market was dominated by two flexographic printing press manufacturers: Mark Andy and Webron. As the need for labels became more complex, other manufacturers like Nilpeter, Comco and the Canadian Primoflex Systems (CPS) started to emerge with novel design features. Today, flexographic printing is competitive with both offset and gravure – and even with digital except for very short runs below 1.000 linear meters! It has been a great deal of progress, and we are proud of the role we have been able to play in fostering this progress through the introduction of innovative flexographic plates and plate processors.”

The introduction of the Apple Macintosh in 1984 had a revolutionary impact on prepress for labels followed by Purup Electronics’ computer imaging systems to market that revolutionized the creation of label images and artwork. This set the stage for many other innovations that have driven the market forward, including the introduction of the first flexographic computer-to-plate system by DuPont at drupa 1995. Today, computers play an integral role in everything from sparking the first design ideas to getting the final product on the shelf. And, of course plates.

Based on Free Radical polymer chemistry, Photopolyme plates continue to undergo development advances that have been critical to the ability of flexographic printing to not only be competitive with other printing technologies, but to become the leading label production printing technology. This is where Asahi’s more than 45 years of experience with innovation in polymers has truly come into play.

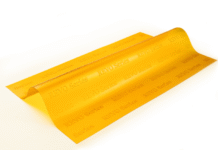

In 1982, Asahi launched Asahi flexo plates family with specific benefits for labels. AFP plates are manufactured using Butadiene and Styrene to improve the malleability of the plate and the drape of the plate around small circumference cylinders. In 1985, Asahi invented the dry germicidal UVC lamp anti-tack process that eliminated the wet process by bromide. Then in 2000, the company began manufacturing the first aqueous plate technology for the label industry. Years later, this was combined with Clean Transfer Technology; the result was plates from Asahi Photoproducts that have been specifically engineered to transfer all remaining ink to the printed substrate.

Asahi’s Clean Transfer Technology has received great market reception in the line of water-washable plates, and the company will now be extending this capability to other plate categories. Not only will this help flexographic printers increase productivity, but it will also extend the range of applications they can offer customers, including the ability to transfer even more work from offset to flexo.

Galton added, “We believe flexography will continue to be the dominant printing technology for labels for some time to come, and in addition to extending Clean Transfer Technology to other plates in our portfolio, we are working hard to continue to bring innovations to market, including both plate and processing technology, so that 45 years from now, we can again look back on a history of innovation and contributions to the market.”