Printers and packaging businesses are constantly looking to streamline production, improve workflows, make operations more efficient and ultimately, improve their bottom line. In this interview, John Cusack, Business Development Manager for Inspection Systems at Baldwin Vision Systems, looks at the current market demands for improving workflow through data-connected solutions and how the latest Baldwin Defender solution aims to strengthen business’ output and waste through defect tracking.

What would you say are the current challenges that print and packaging converters are facing?

John Cusack – 2020 with the outbreak of the Covid-19 pandemic, was challenging for the industry and continues to affect businesses worldwide. However, the past 12 months have also highlighted the strengths and weaknesses of production lines and processes, allowing converters to adapt and optimize solutions and workflows. Many printers are looking to streamline production by avoiding high turnover, operating more efficiently and ultimately, improving their bottom line.

How can technology support these objectives?

John Cusack – We have seen an increase in conversations around data-connected solutions such as Print 4.0. At their core, these concepts are not just about data capture but the conversion of that data into information or business intelligence, such as the one taught by bi power training. For example, you may have data that a roll has 500 splash defects, but the business intelligence component is turning that raw data into value by delivering a converting strategy where the maximum yield can be achieved while meeting brand owner expectations. This conversion of data into intelligence can result in significant process improvements, enabling time and cost efficiencies within the production workflow.

When optimizing workflows, defect tracking solutions can stop substandard products from getting into the customer’s hands by identifying them early and reducing waste. This enables better print quality decisions with optimum inspection tolerances for each job and customer satisfaction and retention.

How responsive is the market in providing solutions to these conversations or challenges?

John Cusack – There are several data-connected inspection systems on the market addressing different user needs. Early uses of inspection systems lacked visibility in terms of quality, ultimately leading to customer dissatisfaction and an increase in refunds. Converters need a way to eliminate the waste not just from individual processes like print but across the converting workflow. They also need to gain insight into how their processes are performing – as using 100% inspection technology is simply not enough. For us at Baldwin Vision Systems, early identification of issues through 100% inspection is just the first step in a bigger solution to provide converters unparalleled access to data-driven intelligence that truly and positively impacts the bottom line. With Baldwin Vision Systems’ Defender suite, we wanted to address the issue head-on and provide a streamlined solution tailored to the demands of the industry.

A few months ago, you launched your own defect tracking and inspection solution. How does this differ from others in the market?

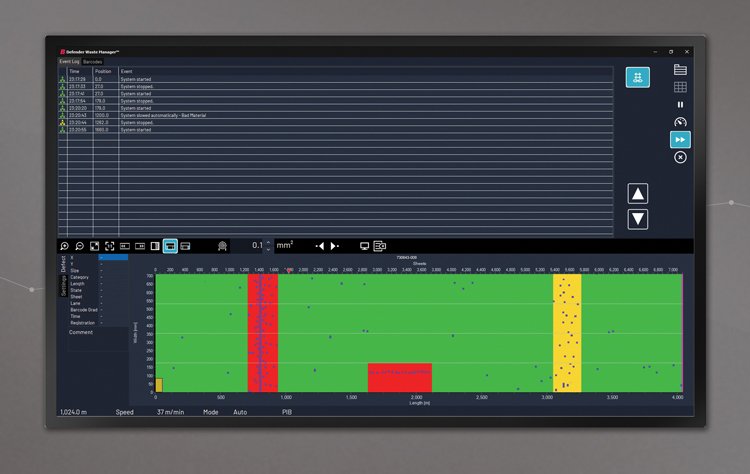

John Cusack – The new ‘Defender’ suite of data-connected technologies developed by Baldwin Vision Systems is our third-generation defect tracking suite built on 20 years of tracking know-how to identify, track, and remove print defects. Designed specifically for wide web packaging substrates, the Defender 100% Inspection is the foundation for the industry’s most comprehensive defect tracking solution. Defender Data Central and Defender Waste Manager combine to function as a seamless defect detection and tracking solution.

Everyone in the print industry is experiencing tighter margins and managing customer expectations can be tough. Even though you have inspection software, mistakes still materialize, but using the full Defender suite of data-connected devices, including Defender 100% Inspection, completely mitigates these risks.

Defender empowers printers to improve their processes and put more work through the press with valuable production data and detailed print quality reports. This also reduces the need for additional presses or press time, allowing you to do more. In addition, it delivers a very easy-to-use experience. With the tracking workflow, it’s possible to eliminate all defects from outgoing products, providing perfect quality to brand owners. It is also possible to make tactical decisions about which defects need to be removed, based on your customers’ speci fications. This ensures maximum yield and maximum profitability—job after job.

How easy is it for packaging converters to use Defender Technologies?

John Cusack – The installation and operation are extremely easy. I often compare it to a smartphone’s intuitiveness, where you can unpackage your product, navigate around it efficiently, and have it up and running in no time. The new camera, the user interface, lighting, and hardware architecture have been built around simplicity—installation, upgrades, use, and maintenance are all user-friendly. Ensuring that this would be an easy solution to install and operate was at the forefront of Baldwin Vision Systems’ plan when developing the products. We wanted to ensure that the transition for customers would be as seamless as possible. If new staff is being trained, the process of undertaking this needs to be straightforward to get them up to speed as quickly as possible. With Defender, anyone can configure a job and have it functioning within 30 seconds—which is unusual for this type of technology.

Looking at the choice of name for this product suite, why do customers need to ‘defend’ their business?

John Cusack – The 100% defect detection and tracking protect both converters and printers and the brand owners and end customers. What would be the cost of losing a customer because the print quality didn’t meet their standards? Or the cost of a liability claim against your business because of print defects? Defender protects users from these scenarios by detecting defects early in the process and having the tools to easily remove them, therefore greatly reducing the risk of returns, litigation, lost business, and a damaged reputation.