Mumbai, India, 22 April 2021, Dow and Lucro Plastecycle, an Indian recycling company, are partnering with Marico to introduce Dow’s post-consumer recycled (PCR) based coalition shrink films for its consumer product flexible packaging. This alliance will help Dow work towards its new sustainability target of stopping waste by collecting 1 million metric tons of plastics to be collected, reused, or recycled by 2030.

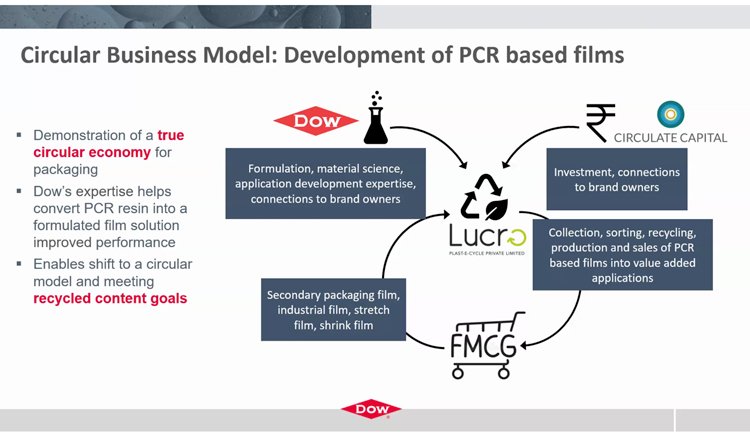

Earlier this year, Dow and Lucro signed a memorandum of understanding (MoU) to develop and launch polyethylene (PE) film solutions. Under the MoU, Dow will utilize its industry-leading team of packaging experts, material scientists, recycling equipment, blown film manufacturing, and testing capabilities to help Lucro develop recycled film for various applications.

With the addition of consumer products manufacturer Marico, the tripartite association helps Dow’s strategy of enabling a circular economy for plastics. “Sustainability is a long-term commitment and a way of life at Marico. We are constantly working towards making a difference by adopting every possible measure that will propel us further along the road to secure a sustainable future. Furthering our ongoing programs towards integrating circularity principles in product packaging, this partnership with Dow is significant as it enables us to use post-consumer recycled resins that help reduce our carbon footprint,” said Jitendra Mahajan, chief operating officer – Supply Chain & IT, Marico.

The strategy focuses on integrating recycled content into product offerings. This type of lateral recycling attempt tries to enhance the value of recycled materials to extend the overall lifecycle of the original polymer and material inputs from creation to use to disposal. Dow’s virgin resins combined with Lucro’s PCR align with a strategy of designing products for circularity and implementing recycling solutions to provide new life for used plastics.

“We are pleased to welcome Marico, a leading consumer goods company in the health, beauty, and wellness space, to join us in leading the way in India by offering circular packaging options,” said Bambang Candra, Asia Pacific commercial vice president of Dow Packaging and Specialty Plastics. “This arrangement places all the valuable stakeholders along the road to sustainability to meet market demands for brands seeking to use more recycled content in their packaging.”

“We have always been passionate advocates for recycling post-consumer waste and believe that there is a lot of value that can be derived from it,” said Ujwal Desai, co-founder and managing director of Lucro. “Collectively between Dow, Lucro, and Marico Limited, we are looking forward to supporting brand owners in meeting their sustainability goals through the development of PCR-based sustainable packaging solutions.”

Our view

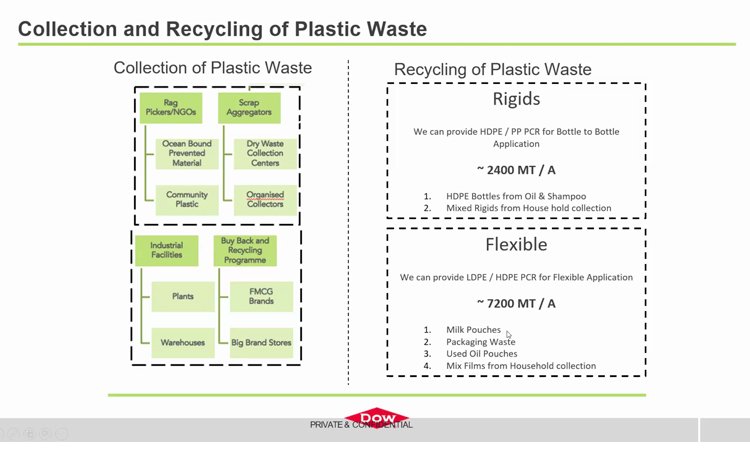

The webinar of 10 February 2021 pointed to the kind of partnership that has just been announced between Dow, Lucro, and Marico. Notably, the webinar looked at the financial investment needed to take this process forward with the participation of Circulate Capital which seems to have both the financial backing and the expertise to contribute to the process that requires both compensation and motivation of the entire supply chain of plastic packaging.

One thought at the time, that this looked like a reasonable proposition or effort, that could get some lateral recycling done in India. There has been quite a bit of talk over the past five years on plastic waste and one looks forward to this combination of committed companies concretely and meaningfully taking the recycling of plastic packaging and the use of post-consumer recycled material forward.