Tetra Pak and Rockwell Automation have announced a strategic business collaboration for cheese and powder solutions. The combined business expertise will deliver data and technology to reduce variability and improve quality consistency, ensuring finished products are produced sustainably and cost-effectively within demand-driven manufacturing environments.

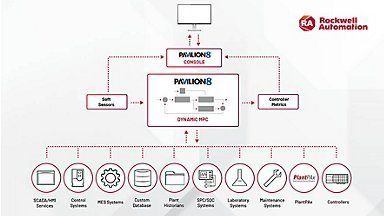

The collaboration – starting with evaporation and spray drying – has resulted in Tetra Pak’s new Powder Plant Booster solution, to be packaged with Rockwell Automation’s Model Predictive Control (MPC) and its Pavilion8 and PlantPAx MPC technology.

Pavilion8 driven Rockwell Automation has shown applications to deliver possible product quality variability reductions of up to 60%, reductions in off-spec products by up to 75%, improved throughputs up to 9%, and reductions in energy per unit of a product up to 9%2. It allows producers to fully optimize their operations – helping them stay competitive while meeting changing market demands.

Fred Griemsmann, Vice President Cheese & Powder Systems at Tetra Pak says, “The food and drink industry now requires that producers have a level of agility never seen before. It means we must be ready to offer our customers advanced processing control technology that is both flexible and precise. Customers can leverage our food application expertise, have access to production data in real-time, and adapt their process variables to match requirements – without any loss in quality, productivity, or throughput. This unique collaboration with Rockwell Automation provides the foundation upon which this capability is based.”

Matthew Fordenwalt, VP GM, Systems & Solutions, Rockwell Automation, says, “Rockwell Automation is delighted to build upon a relationship that spans 35 years and collaborate with Tetra Pak, a company that shares our view that deeply understanding customers and their best opportunities for productivity creates value. We believe shared customer insights, coupled with technology and domain expertise, will deliver real value-focused outcomes to the industry.”

The Powder Plant Booster solution – with complementary Pavilion8 software – is a process modeling, advanced control, and optimization platform that integrates with any control system to provide real-time insight, diagnostics, and advanced control continuously. It achieves this by delivering an intelligence layer on top of basic automation systems, which, due to its built-in performance metrics, continually drives plants towards addressing multiple business objectives.