Emmi Caffe Latte, one of the ready-to-drink iced coffee brands in Europe, has started to incorporate chemically recycled polypropylene into its packaging. The cups are produced by Greiner Packaging and the chemically recycled material comes from Borealis, one of the world’s providers of advanced and circular polyolefin solutions based in Vienna, Austria.

Emmi, Switzerland’s largest milk processor, is committed to climate protection and the circular economy. The dairy company has the stated goal to make all of its packaging 100% recyclable and is committed to various measures to promote circularity such as packaging that contains at least 30% recyclate by 2027. Focusing on recyclable packaging and the use of recycled materials, Emmi is taking a first step with its Emmi Caffe Latte brand.

Material scarcity and environmental policy

From September 2021, Emmi’s brand of chilled coffee drinks, Emmi Caffe Latte, will use at least 100 tonnes of plastic based on the recycled material each year. Chemical recycling renews plastic back to plastic creating recycled materials with a level of purity equivalent to fossil-fuel-based PP and hence, fit for protective, food-safe, and other demanding applications. In this way, Emmi is utilizing difficult to recycle feedstock preventing plastic waste that would be likely landfilled or incinerated. In the future, depending on the availability of suitable material, the amount of recycled plastic in Emmi Caffe Latte packaging is to be further increased.

The new technology to recover polypropylene is currently still in its infancy, where Greiner Packaging and Borealis are leading the way. Only limited quantities of chemically recycled polypropylene are currently available, and Emmi is one of only a few food manufacturers to have secured a share of the chemically recycled polypropylene plastic through its early commitment and long-standing collaboration with the development companies.

“It takes joint efforts by food and packaging manufacturers to reduce waste and make measurable progress in the circular economy,” says Bendicht Zaugg, who is responsible for Sustainable Packaging at Emmi.

“We have had a long and rewarding partnership with both Emmi and Borealis,” says Greiner Packaging key account manager Vincenzo Crescenza. “This achievement is in line with our stated goal to work towards achieving a circular economy. Our strategy is to develop innovative products, develop new service partnerships and business models, and pioneer materials partnerships.”

“Borealis looks forward to a world without plastic waste,” says Trevor Davis, head of Marketing, Consumer Products at Borealis. “The chemically recycled polypropylene used in this new Emmi Caffe Latte cup is manufactured with Borealis Borcycle portfolio of transformational chemical recycling solutions, giving polyolefin-based, post-consumer waste another life. It offers all-round benefits enabling the transition to a circular polyolefin industry whilst creating virgin quality plastic products. By staying true to our EverMinds ambition of accelerating action on circularity, together with our valuable partners along the whole value chain such as Emmi and Greiner Packaging, we are reinventing for a more sustainable living.”

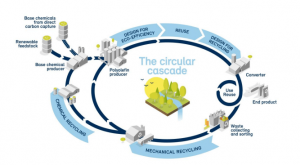

plastic waste back into chemical feedstocks, chemical recycling is part of the solution to improve

recycling rates while diverting plastic waste from landfills or incineration. Illustration Borealis

The chemically recycled material used for Emmi Caffe Latte cup consists entirely and solely of ISCC (International Sustainability and Carbon Certification) material, on a mass balance basis. Mass balance is a methodology that makes it possible to track the amount and sustainability characteristics of circular and/or bio-based content in the value chain and through each step of the process. This provides transparency ultimately also to the consumers, enabling them to know that the product they are buying is based on this renewable material.

Packaging facts:

- Technology: Injection molding

- Decoration: Sleeve

- Material: 30% Borcycle chemically recycled PP

Recovering plastic from plastic packaging – Chemical recycling enables chemical raw materials to be recovered from plastic waste that is otherwise difficult to recycle mechanically – an important part of the solution for increasing recycling rates, and for preventing plastic waste from being landfilled or incinerated and thus keeping it in the cycle as a raw material. These materials have the same properties as plastics from traditional production (“virgin plastics”) and are approved for use with food.

Greiner Packaging is a European manufacturer of plastic packaging in the food and nonfood sectors. The company has enjoyed a reputation for outstanding solutions expertise in the fields of development, design, production, and decoration for more than 60 years. Greiner Packaging responds to the challenges of the market with two business units – packaging and assistec. While the packaging unit focuses on innovative packaging solutions, the assistec unit is dedicated to producing custom-made technical parts. Greiner Packaging employs a workforce of nearly 4,900 at more than 30 locations in 19 countries around the world. In 2020, the company generated annual sales revenues of EUR 692 million (including joint ventures, approximately Rs 5,988 crore), which represents approximately 35 percent of Greiner’s total sales.

Emmi claims to be the largest milk processor in Switzerland. Its roots go back to 1907 when it was founded by 62 dairy farmer cooperatives around Lucerne. Over the past 20 years, Emmi has developed into an international, listed group of companies. In doing so, Emmi has followed a long-standing, successful strategy based on three pillars – strengthening the Swiss home market, growth abroad, and cost management. An important credo that has accompanied Emmi throughout its corporate history is a strong sense of responsibility towards people, animals, and the environment. In Switzerland, Emmi produces a full range of dairy products for its own brands and customers’ own brands, including export hits such as Emmi Caffe Latte and Kaltbach. In addition, there are locally manufactured products depending on the country – mostly in the specialties segment. In addition to cow’s milk, goat’s and sheep’s milk is also processed.

The Emmi Group has 25 production facilities in Switzerland. Abroad, the company has subsidiaries in 14 countries, including production facilities in 8 of them. Emmi exports products from Switzerland to around 60 countries. In addition to its home market of Switzerland, the company’s business activities focus on Western Europe and the American continent. Sales of CHF 3.7 billion (approximately Rs 29,674 crore) – around 10 % of which comes from organic products – are divided roughly equally between Switzerland and other countries. Of the almost 8,900 employees, more than two-thirds are now employed at locations outside Switzerland.

Borealis is one of the world’s providers of advanced and circular polyolefin solutions and a European market enterprise in base chemicals, fertilizers, and the mechanical recycling of plastics. The company leverages its polymers expertise and decades of experience to offer value-adding and circular material solutions for key industries. In reinventing for more sustainable living, Borealis builds on its commitment to safety, its people, and excellence as it accelerates the transformation to a circular economy and expands its geographical footprint.

With head offices in Vienna, Austria, Borealis employs around 6,900 employees and operates in over 120 countries. In 2020, Borealis generated EUR 6.8 billion (approximately Rs 58,863 crore) in sales revenue and a net profit of EUR 589 million (approximately Rs 5098 crore). Austrian-based international oil and gas company OMV Group owns 75 percent of Borealis, while the remaining 25 percent is owned by a holding company controlled by Mubadala, which is headquartered in the United Arab Emirates. Borealis supplies services and products to customers around the globe together with two important joint ventures – Borouge (with the Abu Dhabi National Oil Company, or ADNOC, based in the UAE) and Baystar (with Total, based in the US).