Mumbai-based packaging major TCPL Packaging has recorded robust growth in its flexible packaging division this year, looking at over a 50% jump in revenue. About a year ago, the company had wrapped up a major investment drive in its flexible packaging vertical, which it started in Silvassa in October 2016 with a 9-color Bobst rotogravure press and a full-fledged converting section.

“Our flexible packaging business has notched up solid topline growth this year. We are looking at over a 50% jump in revenue for FY23. The new capacity we built in the latest investment drive has been almost fully utilized. Earlier we were printing, converting, and supplying about 400-500 tons per month. Now we are doing about 800-900 tons a month,” says Vidur Kanoria, associate director at TCPL Packaging. Kanoria manages the company’s flexible packaging operations.

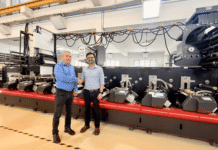

TCPL’s flexible packaging division runs two Bobst rotogravure presses. The latest Bobst, which was added in the recent investment phase, is a 10-color press with a production speed of 350 meters per minute and a width of 1,300 mm. The press has a movable turner bar and can be run in 8+2 and 9+1 color configurations. The Bobst press contains TAPS – the total automatic pre-register system by which the register settings for the entire press are done with a single button without any other operator intervention.

The company also added a co-extrusion lamination line, another Nordmeccanica laminator, and slitters, besides center seal and gusseted pouch-making machines.

Kanoria says TCPL is also manufacturing PE films in-house through its subsidiary, TCPL Innofilms. “The fact that we are producing PE films in-house has added a lot to our capabilities. We can now make faster supplies as previously we were buying films from third parties,” he adds.

TCPL has added two pouching machines from Galaxy Packtech, which are now fully utilized. A third one will be installed at the Silvassa plant in January.

“The third pouching machine is for flat bottom pouches. This is a new segment for TCPL and will give us access to a whole new market, especially in exports. We are also looking at an automatic spout fixing machine and have to order more stand-up pouch machines,” he says.

Given the growth of TCPL’s flexible packaging business, plans are afoot to add a third printing line. “Within a year of our last investment and expansion drive, we are at a stage where we need to further boost our capacities. We are planning a third printing line, which we will finalize in the next two to three months. We are looking very closely at coating lines as well, to be prepared for the increased use of water-based barrier and heat seal coatings” he adds.

Reifenhauser blown film line with MDO unit

In the last investment phase, the company bought a Reifenhauser EVO Ultra Stretch 5-layer blown film line with an MDO unit, critical for adding various attributes and properties that improve PE films by stretching the film in the machine direction. The blown film line, with a height of 25 meters and a width of 3 meters, is used to manufacture MDO-PE films, which when used in mono polymer laminates are inherently easier to put into the polyolefin mono-material family waste stream for 100% recycling.

Kanoria says that the adoption of MDO-PE films is a little slow in India right now because of the premium involved and also because the prices of polyester films have decreased sharply in the last few months.

“When it comes to MDO-PE films, the progress is a little slow because of the costs involved. The prices of polyester films have crashed in recent months. The prices of PE films have also come down but not as sharply. Brand owners need to do a lot of transition trials before they shift from MDO-PE films to polyester films. At TCPL, we have conducted successful trials of MDO-PE films on products such as wet wipes, atta, rice, detergents, and shampoo. These are quite close to being commercialized. We are exporting MDO PE films and have the capacity to produce about 400-450 tons every month. We are also using the machine to produce in-house PE films,” Kanoria says.

Flexible packaging growth

TCPL continues to be very bullish about the medium and long-term growth of its flexible packaging division.

“As I mentioned, our flexible packaging business has done reasonably well. We are planning another expansion within one year of wrapping up the last phase. Once the next phase of expansion is over, our Silvassa flexible packaging unit will be quite big. Not many players would do so much stuff at a single site. We do general laminates, a lot of surface printing on aluminum foil, we do shrink sleeves and pouches, print on very thin paper and board, and now we make our own sealant films as well as the InnoPure range of MDO PE films. The increased focus on sustainability is an added advantage, all from one site,” Kanoria says.

The company is eyeing a bigger share of the export market, especially in North America and Europe, and is open to the idea of setting up a flexible packaging unit in either north or south India.

“We are excited about the potential of our flexible packaging division, be it the domestic market or exports. Our Silvassa plant is working well. But if need be, we are open to setting up a new flexible packaging plant in north or south India. It all depends on the market dynamics and return on investment,” he concludes.