The 9-color Gallus ECS 340 installed at the Monarch Graphics plant in Noida has been commissioned and is fully operational since mid-March 2015. Bhrigav Jain is impressed by the efforts put in by the Gallus engineers for its perfect installation. He says, “This Gallus label press comes in the size of 340 mm and the extra 10 mm which it provides against other conventional presses makes a lot of difference. Although it is an expensive product, to me, it’s a value for money proposition and it is not difficult to see why it has met with a lot of success in India. The learning curve has been easy and I am very satisfied with the machine so far.”

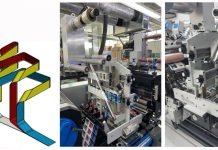

The Gallus ECS340 is a cost-efficient, high-quality label production press according to Jain. With its granite core, the press is exceptionally quiet, stable, with minimal waste and set-up times. For rapid design and color changes, the fully servo driven press allows register presetting and the extremely short web path of just 1.1 metres between printing units cuts waste significantly, according to Jain. The self-explanatory touchscreen technology means faster learning for operators and quicker makereadies at sustainably high quality levels.

Monarch’s ECSalsohas a rotary screenunitfor extraordinary textures and visual effectswhile the entire configuration optimizes print value while minimizing operational costs.

The new label press is an ambitious project but Jain is confidentthatthe amount of added value thatitwill provide to his customers would be hard to beat. “From making designs, to

makingprototypes andshortrunsamples fortestingandthen turning them into full production runs – at Monarch Graphics we offer the complete range of services to our customer. Bhrigav’s fatherPavail Jainhasbeeninthe label industry formore than 30 years and apartfrom his enormous experience he has a tremendous understanding of the needs of consumer product companies. Pavail Jain says, “The quality, flexibility and reliability thatwe provide is our strong point and we now have one of the best technologies on offer to back our claims.” The Monarch plant has 80 tonnes of air-conditioning to support the dust free and temperature controlled press rooms. In addition there is full UPS backup since the presses rely heavily on electronics and computerized controls and diagnostics.

With the addition of the new ECS label press to the existing Orthotec and with the imminent installation of a Tech Nova digital label press, Monarch Graphics is focussing on the food and beverages segment along with pharma and speciality opthalmic product labels. The company plans to extensively if not exclusively use low migration inks to produce safe, hygienic and environmentally friendly labels for use by global manufacturers and exporters.