New Delhi headquartered Packtime Innovations has invested in an Omet Xflex X6 narrow web flexo combination printing and converting press. The Xflex has been installed at the company’s plant located in Pune in Maharashtra. The machine is a 530 mm wide 8-color press with full UV and hot air curing options. The press configuration includes a rotogravure station, two corona treaters, a web cleaner and a camera system.

Commenting on the equipment Anand Singh, vice president – Technical at Pactime Innovations said, “Omet machines are robust, operator friendly, ergonomically designed and adaptive to various inline processes. Overall, the machine is supported by the highly skilled, knowledgeable, humble and polite Omet team without whom such engineering marvels can’t be innovated.”

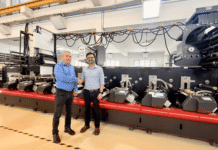

The sale and installation has been handled by Omet’s exclusive Indian agents Weldon Celloplast based out of New Delhi. Kanwardeep Sahni, director of Weldon said, “Packtime is a very prestigious customer and will be creating innovative labels and packaging with the Omet XFlex X6.”

The Xflex X6 flexo press is seen as a solid pay-back investment for any company looking for high productivity, efficiency and astonishingly good printing results. It is able to integrate several printing and converting technologies in-line and process all kind of substrates, from 12-micron film to light cartons, producing many types of applications to satisfy the requests of different target markets. It has operator-friendly features like fully removable inking cassettes and light ink pans, automatic set-up and pre-registration, easy link to intranet and ERP.

It’s Flexo Direct-Drive technology and gearless concept allows the press to reach the very high quality with no backlash and perfect register stability, even at the highest production speeds. The modular design allows the label printer to combine and implement in-line, without limitations, various printing technologies, as well as special finishing applications and converting units–to achieve a final product in a single pass. The FDD can control both machine and cross side of each printing unit in real time to get the machine ready to print in less than a minute, while generating minimal waste.