One of India’s leading packaging printing companies, Indore-based Pragati Graphics, has added Baldwin Guardian OLP offline proofing and inspection detection workflow. This installation is the first of its kind in India.

The Guardian OLP verifies that the files used for production — or the beginning-of-run press samples — match the customer-approved master file 100%. By comparing any pre-press file or scanned press sample to the customer-approved original in seconds, advanced software automatically locates and highlights differences in print quality. The system can compare one-up electronic files or scans to multi-up electronic files or scans and detect printing defects, such as missing or extra print, pre-press errors, plate defects, and color variations.

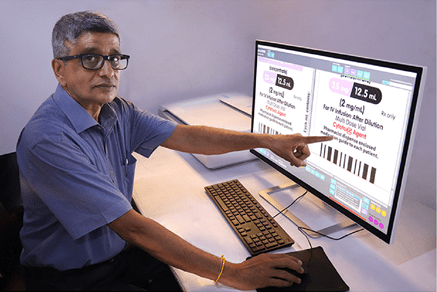

“We print many jobs in different languages and important segments, such as pharmaceutical. A small mistake can quickly result in a large expense in terms of time and materials wasted, but more important, in terms of the satisfaction of our customers,” Rajesh Nema, Pragati’s executive director, commented. “We expect the Guardian OLP to quickly pay for itself by providing quality assurance to our current customers and giving Pragati a competitive advantage to attract new brand owners and print buyers. Guardian OLP fits in perfectly with Pragati’s mission to provide absolute print quality on every print run.”

Pragati Graphics’ product line includes monocartons, self-adhesive labels, pharmaceutical leaflets, and flexible packaging laminates, among others. Some of its customers include Gujarat Milk Marketing Federation, Parle Biscuits, Ruchi Soya Industries, Cadila Pharma, Lupin, and Torrent Pharmaceuticals. Nema also serves on the board of the Label Manufacturers Association of India (LMAI) and is its honorary general secretary.

“The system is very easy for operators to learn and adds production efficiencies by saving job information for later use. This reduces set-up time for future runs. Printers can minimize liability and provide traceable proof of quality through measurement and reporting. Most important, Pragati can be assured that a printed product with minuscule errors will not get into its customers’ hands. It is difficult to place a monetary value on earning complete trust from your customers,” Hemant Desai, director of the Baldwin Vision Systems India office, said.