Seattle-based Richmark Label has recently doubled its investment with Bobst by adding another two UV inkjet presses to the first two installed in early 2021. All four digital machines leverage Bobst Digital Inkjet Technology delivering unrivaled speed, quality, and productivity. One of the country’s oldest pressure-sensitive label companies, Richmark Label, was established over 70 years ago and now resides in its third location in Seattle’s historic Capitol Hill neighborhood. It manufactures a wide variety of prime labels for customers in all 50 US states.

In October 2020, Richmark invested in two Bobst digital label presses – an LB701-UV and an LB702-UV, to replace its original and aging presses. The plan was to replace the existing presses with presses that could deal with its short runs and handle much longer runs that were being run flexographically. Before choosing the Bobst presses, Bill Donner, Richmark Label’s President, looked at several options. According to Bill, the presses had the best combination of quality, speed, and price of anything he had seen without the drawbacks he definitely didn’t want.

“Our average job order was about US$1,000, so we needed an efficient, cost-effective press for our current short runs and one that would also be right for the longer runs we wanted to transfer from our flexographic presses. So we chose the LB701-UV and LB702-UV presses and were so impressed that we bought two more a year later.”

“The print quality is every bit as good as we expected, and the ease with which our people were able to learn to operate them has been even better than we expected. In addition, the set-up time, which is critical for short-run orders, is excellent, and the press speed for many orders is unbelievable,” Bill said.

The perfect inkjet fit developed by Bobst

Wholly developed and owned by Bobst, the digital inkjet technology powering the LB701-UV and LB702-UV delivers a high native resolution of 1200 x 1200 dpi. In addition, they afford Richmark fast and easy industrial label production, allowing them to print on a wide range of substrates, including paper, self-adhesive and flexible materials, proving more efficient than even the most cost-effective traditional processes.

The larger of the two, the LB702-UV, cost-effectively addresses 90% of all label jobs up to 26,000 linear feet in length, with the capacity to print over 2.1 million square feet a month at a printing speed of up to 330 feet a minute. The LB701-UV, meanwhile, can produce 800,000+ square feet of labels a month, printing at 230 feet a minute. In addition, both presses achieve fast and frequent changeovers with a short web path that reduces set-up times and waste, making them a very sustainable option for label companies.

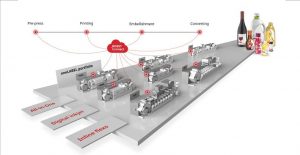

Having been convinced that the technology would be the perfect fit for the business, Richmark Label also chose to partner with Bobst because of Bobst’s strong vision, which focuses on innovation in digitalization, automation, connectivity, and sustainability.

“The digital market is fast evolving, so we needed a partner with a clear path towards the future. The Bobst team also has an incredible knowledge of digital print and a deep understanding of the labels market. These were key components in our final decision process,” concluded Bill.

“As part of the Bobst oneLABEL portfolio, the Bobst UV inkjet printers offer limitless, profitable digital label production, and they have taken Richmark Label to the next level in their evolution,” commented Dean Haertel, business director oneLABEL, North America. “With four of these ultra-productive and cost-efficient machines in house, they can guarantee the fastest delivery, highest quality, and most competitive prices to secure their place as a leading label supplier.”