Woojin Plaimm, a South Korean manufacturer of plastic injection molding machines with offices in India, has announced a collaborative initiative to advance sustainable material processing by supporting the commercialization of an innovative eco-friendly material called CXP (Cellulose Cross-linked Polymer). In collaboration with a local forestry cooperative and a domestic CXP developer, the company is developing and supplying dedicated injection molding systems optimized for the unique properties of CXP.

The tripartite partnership brings together key players across the value chain – the forestry cooperative provides biomass by-products such as wood chips and agricultural residues, the CXP developer conducts material R&D, and Woojin Plaimm is responsible for manufacturing the custom-tailored injection machines required for molding CXP.

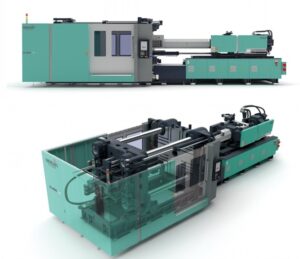

The DL-G5 tailored for CXP

To address the specific challenges of processing CXP—such as carbonization at relatively low melting points — a dedicated injection molding machine, the DL-G5 a two-platen direct pressure machine features a custom screw design that minimizes frictional heat and optimizes low-temperature melt flow, significantly reducing the risk of carbonization and gas emissions during molding.

Key technologies integrated into the DL-G5 include a servo pump system for energy efficiency; fast dry cycle (6.0 sec at 1800 tons EUROMAP 6); half-nut synchronous locking for reduced cycle time; and, a modular controller with multilingual support. The machines also features an integrated inverter cabinet, ball-bearing linear guides for reduced friction and enhanced precision, high-rigidity dual-axis rods and closed-loop backpressure control, enhancing repeatability and responsiveness in CXP molding.

Global market strategy and K 2025 participation

Woojin is actively preparing to expand this solution globally with its two branches in Chennai in Tamil Nadu and Anantpur in Andhra Pradesh in India serving as key contact points for inquiries in the respective markets, with dedicated sales and support networks already in place. Additionally, the manufacturer plans live demonstrations of its CXP molding capabilities at K 2025, to be held in Düsseldorf, Germany, from October 8 to 15, 2025. The demonstration will feature the TE250NC, an electric two-color injection machine processing CXP resin on-site.

The South Korea based company operates the world’s largest single-site plastic injection molding machine production facility and conducts global business through 42 branches in 27 countries. Its product range includes hydraulic, electric, hybrid, horizontal, vertical, and tiebar–less injection machines, along with solutions for foam injection and customized applications. Apart from its cutting-edge engineering capabilities Woojin Plaimm is positioning itself as a strategic supplier with its environmentally responsible material innovation for sustainable manufacturing.