At Labelexpo Europe 2017, slated to be held from 25-28 September, leading companies will launch new products and display their latest solutions for the label and packaging industry. Over the four days, 650 exhibitors will showcase their latest products and solutions across nine halls.

API, Hall 6 Stand A23

API, a leading manufacturer and distributor of foils, laminates and holographic materials, will launch its new and improved TA+ cold foil. Visitors can discover how the TA+ cold foil, API’s most advanced cold foil to date, offers pack designers and printers exceptionally fine detail and the capability to cover large solid areas, as well as outstanding over-printability, meaning there is no limit to the range of colors and effects they can produce. Also on display will be the company’s custom decorative holography service, Holonique Boutique, through which it provides customers market-leading expertise in the use of holography

and 3D designs.

Avery Dennison ,Hall 5 Stand A31

The company will introduce a number of significant innovations designed to drive sustainable growth at Labelexpo Europe 2017. The exhibition stand will feature five interactive zones, focusing on the key benefits of enhanced shelf appeal, performance, sustainability, intelligent solutions and compliance and services. The company will demonstrate its latest solutions including MC FSC recycled paper facestock, Sensorial Collection of textured label materials, and Clear Hotmelt adhesive for chilled food labels.

The ultra-clear, non-yellowing S2405C hotmelt adhesive offers both the tack and application temperature of a conventional hot melt adhesive without the yellowing. Offering a straightforward and competitive solution for a ‘no label’ look for chilled foods, the S2045C adhesive also delivers a lower total applied cost as it does not require a barrier-film facestock.

Bobst, Stands 3A58, 3A60 & 3A64

At Labelexpo Europe 2017, Bobst will feature equipment in operation, engaging presentations, and connectivity displays. As many as three narrow mid-web inline UV flexo printing presses will be demonstrated at the company’s stand—the M5X, the M1 and the M6 lines—all in their latest configuration and fitted with enhanced features. These presses are based on Bobst’s 2015 acquisition of Nuova Gidue and rebranding as Bobst.

Visitors will also learn about the vast and comprehensive range of web-fed solutions Bobst offers in the different segments of the label industry. These include the latest developments in CI flexo, gravure printing and lamination, which are especially suited for customers looking for efficiency in short-run production. Also, visitors can hear more about the Bobst range of silicone, adhesive and pre-/ post-metallizing coating lines and vacuum metallizing solutions, including the new K5 EXPERT and AluBond process for high adhesion.

Garware Polyester, Hall 3 Stand E70

India’s Garware Polyester will display PET high shrink film (PETG), PET lidding films (lock seal & peelable-sealable with anti-fog), PET & BOPP coated labels, PET release liner, PET matt film, PET white opaque films, Wet & Thermal lamination films. Apart from these, the company will also have on display motor insulation films and low oligomer films. The company has recently introduced innovative products like PET shrink film with optical brightener, PET shrink film with UV inhibitor, PET medium shrink, PET white shrink, low shrink force high shrink film, and more.

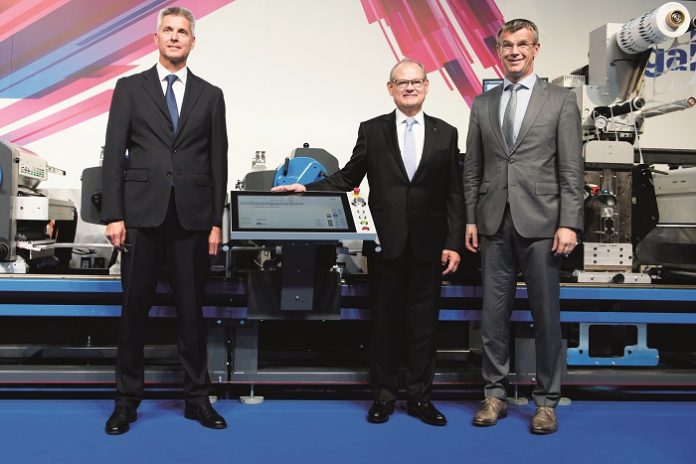

Gallus, Hall 5 Stand B28 and 5C31

Gallus will launch the Labelmaster 440 at Labelexpo Brussels. This is a platform press configured with modules consisting of two printing units each. Various levels of automation are available from ‘entry evel’ to ‘advanced.’ The press is controlled centrally via an HMI touch panel, although manual intervention is also supported. New lightweight aluminum printing cylinders have been specially developed for the press.

IST METZ, Hall 5 Stand D21

UV specialist IST METZ will be presenting the MBS range with its standard Hot Swap functionality. The company will also present the buy one, try one concept for the first time, enabling customers to test the new high-performance LED system for free. The company will give customers the option of trying out the MBS LEDcure solution for free for a month when they purchase MBS Lampcure.

IST METZ’s Hot Swap concept enables users to switch between the tried-andtested UV lamp technology and new LED technology at any time during the production process. During the switch-over, the outer housing remains in place on the machine.

Klöckner Pentaplast, Stand 3E74

A global leader in rigid and flexible packaging, printing and specialty solutions, Klöckner Pentaplast will exhibit its line of innovative label films for packaging at the upcoming Labelexpo Europe. In addition, Pentalabel eklipse, a state-of-theart light blocking film, is nominated as a finalist in the Industry Label Awards. Winners will be announced during the exhibition.

Mark Andy, Hall 4 Stand C45

Mark Andy will be showcasing its portfolio of narrow-web technology. The company will have on display an updated Performance Series P7 platform, boasting direct servo improvements, a fully automated job register, and a more ergonomic design to elevate operator experience. There will also be live demonstrations of Digital One, an entry-level short-run label press, throughout the duration of the event. In addition to Mark Andy label technology, representatives from Rotoflex and Mark Andy’s customer support teams will be available at the company stand.

Mouvent, Hall 3 Stand A60

Mouvent will be at Labelexpo 2017 alongside its co-parent Bobst to reveal its first ever range of label printing solutions in action. These include two all-new, high-speed 7-color UV ink printers (LB701 UV and LB702 UV) and a groundbreaking digital inkjet label printer in the narrow web segment that represents a ‘game changer’ in the industry. The web presses print on various substrates such as paper, self-adhesive labels and flexible materials, with widths from 170 mm to 340 mm. Production speeds can reach up to 100 minutes a minute with a native resolution of 1,200 x 1,200 dpi and an optical resolution of 2,000 dpi.

MPS Systems, Hall 11 Stand C20

Dutch printing press manufacturer MPS Systems will launch at Labelexpo Europe 2017 an innovation called ‘talk to me’ aimed at promoting interaction between MPS printing presses and Management Information Systems (MIS). The new MPS connectivity technology allows for real-time data exchange and control at any given moment.

In addition to the regular MIS interface, press operators can be given access to extended ‘anytime, anywhere’ functionality via the specially developed ‘talk to me’ app. The company will also display a second fully equipped EF press at the Automation Arena (Hall 11), organized by Tarsus.

POLAR, Hall 5 Stand C31

POLAR will showcase its highly automated LabelSystem DC-11plus. With a capacity of up to 1,440 label packs per hour, the DC-11plus die-cutting system sets the benchmark in wet-glue label production. This will be the first presentation of POLAR with its cooperation partner Gallus. POLAR LabelSystem DC-11plus is designed for the highly-automated in-line production of banded die-cut labels.

QuadTech, Hall 3 Stand B52

QuadTech will show its extensive range of color management and defect management solutions at Labelexpo. Visitors to the QuadTech stand will see live demonstrations of ColorTrack, QuadTech’s latest color workflow solution for packaging printers. Also featured will be QuadTech’s Color Control with SpectralCam, which compares color accuracy to desired targets—inline, during the print run— and detects any variation. Among the innovations featured at the show will be QuadTech’s Color Measurement with DeltaCam, launched at last year’s drupa. The system makes advanced, inline spectral measurement affordable to individual packaging print houses.

QIPC, Hall 6 Stand D18

Q.I. Press Controls (QIPC) will showcase IBS-100 (Intelligent Bar Sensor – 100% full inspection). This is the first product out of the acquisition of the assets of INTRO International by QIPC. The unique, innovative system enables 100% full inspection and can be combined with existing register, density measurement and control software from QIPC. To measure the quality in digital printing, QIPC detects with the IBS-100 any missing jets from the print image or register mark.

RotoControl, Hall 7 Stand D42

RotoControl, a manufacturer of leading-edge label slitter-rewinder inspection and finishing machines, will have live demonstrations of the BL-series for high-speed production of booklet labels.

The RotoControl high-speed BL-series machine is a modular solution for ECL/booklet label processing with various sizes and formats. A wide variety of optional modules including lamination, screen printing, cold foil, hot melt unit, and flexo printing are available, delivering a complete offline solution in one machine.

Rotoflex, Hall 4 Stand C45

Rotoflex will present a diverse range of offline inspection, slitting and rewinding solutions. As a total solutions partner of Mark Andy, Rotoflex’s business responsive technologies will be presented with live demonstrations.

Making its debut in Europe, the Rotoflex HSI with a horizontal design is meant for high volume label slitting, inspection and rewinding. The HSI is built with an extralarge inspection table, 37 inch (940 mm) high editing area, and an easily accessible slitting module. The servo-driven VSI is the Rotoflex flagship slitter rewinder for traditional

roll-to-roll label inspection and finishing. Live demonstrations of the Rotoflex VLI for offline finishing of tensionsensitive unsupported film will also be shown in Hall 4 on the EyeC Stand C61, integrated with the EyeC ProofRunner delivering 100% print inspection running at speeds of up to 600 meters per minute (2000 fpm).

TRESU, Hall 7 Stand D53

TRESU Group will highlight its comprehensive range of ancillary products for controlling ink flow in flexographic label and package printing situations, along with video presentations of its complete printing and converting lines for lottery and game cards. TRESU’s ancillary program includes an extensive range of chamber doctor blade systems for narrow, mid and wide-web flexo applications, as well as ink supply systems, providing a complete solution

for automating ink flow throughout the flexo press—from bucket to substrate.