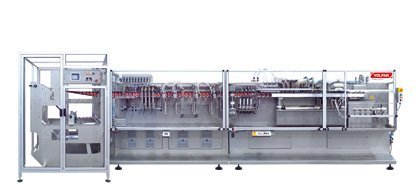

Volpak offers a complete line for the packaging of confectionery products, from pouch to case, ready to display. Pouches with a convenient and functional opening and re-closing system gives you the chance to open it, use its content and close the package at your convenience. The line is composed by three different machines – SP-90 (pouching machine), Pak 1312 (cartoner machine) and Daina 200 (case packer machine). The pouch machine is the SP-90 with weight control, a model which has been developed to offer high production rates, manufacturing flat pouches with a zipper, capable of achieving a speed up to 280 packages a minute. It’s a compact model, featuring the individual adjustment for each pouch forming, which ensures a very good quality finish. The zipper applicator is available to work with the press-to-close or the Velcro type system. The direct weight control is compact, designed to greatly optimize the line’s space. Once the pouches are sealed, the transfer machine leaves them directly on the static weight controller. Another pick and place system gets the pouches…

Choose your subscription to read more

Trial

- ₹ 0 for 4 weeks*

PSA Plan 1

- ₹1,500.00 for 1 year*

PSA Plan 2

- ₹2000 for Year*

PSA Plan 3

- ₹3,600.00 for 2 year*