At the 12th Specialty Films & Flexible Packaging Global Summit & Expo 2025 in Mumbai, Steve Smith, Principal Consultant at Miraclon, outlined the company’s vision for flexographic printing in India, emphasizing its role in delivering efficiency, consistency, and cost savings to brands and converters amid growing market pressures.

Smith’s presentation and our discussion centered on one main point: efficiency, sustainability, and cost savings are best achieved by understanding the entire process, standardization, and prepress techniques, rather than making corrections on press. Tinkering on press costs valuable time and materials.

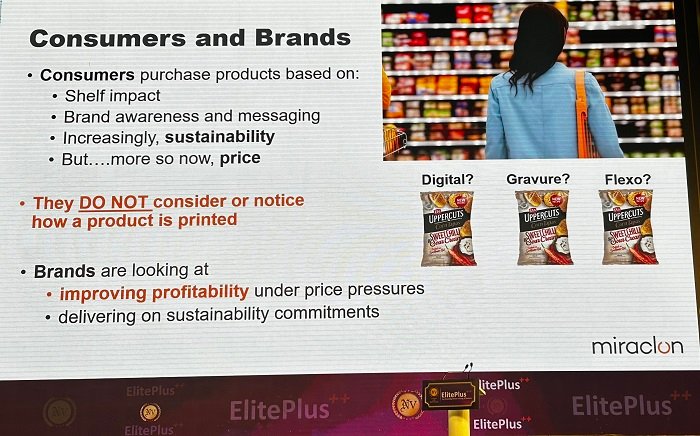

Miraclon’s mission, expressed as “making packaging better for everyone,” centers on helping brands reduce costs while meeting sustainability expectations. Smith explained that although alternative substrates can raise costs, consumers rarely pay a premium—so cost-efficiency without sacrificing quality is essential and flexo enables this balance.

Flexo’s momentum in India

Gravure has long been the dominant process in India, owing to its speed and cost efficiency at very high volumes. However, flexo has made steady inroads, particularly as brands demand shorter runs, faster product launches, and improved sustainability. Smith said modern flexo eliminates the expense and inflexibility of cylinders while providing efficiencies in prepress, faster turnaround, and consistent results that align with brand owners’ priorities.

“With today’s flexo plate technologies, you get predictable results, less waste on press, and faster color approval,” he said. “That makes flexo highly relevant in a market where converters and brands are under constant time and cost pressures.”

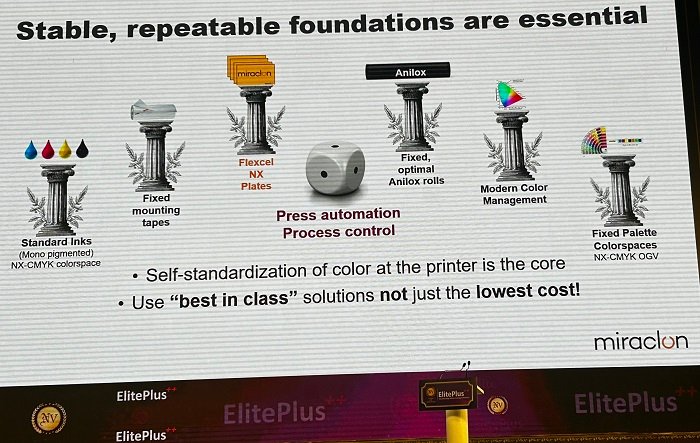

Standardization and efficiency gains

A key part of Miraclon’s offering is standardization, something that it does in a hands-on practice at converters, especially those looking to reduce special colors by using fixed color sets on press. According to Smith, too many converters underestimate the variabilities in prepress workflows and on the press, from dot gain, registration, or substrate stretch.

Miraclon addresses these challenges through plate technologies that enhance imaging precision and reduce variability on press. Smith highlighted the company’s advanced cell pattern plates, which improve ink transfer and predictability. “Our customers are able to achieve at least 10% savings compared with conventional plates when you factor in faster make-readies, lower ink consumption, and fewer wasted metres of substrate,” he said.

Technical innovations in dot structures

Miraclon has also invested in dot engineering. Traditional flexo dots often struggled in highlights or with edge sharpness. Smith pointed to Miraclon’s development of multi-pattern dot structures and microcell technology, which allows printers to hold extremely small dots—down to 1%—reliably. Each dot incorporates engineered surface microcells that control ink transfer, preventing flooding in solids or weak highlight reproduction. “The result is vibrant, consistent print across solids, fine text, gradients, and the full tonal range,” he said. “It’s about giving converters repeatability and brands the confidence of color fidelity.”

Expanded color gamut in packaging

Smith also stressed the growing importance of expanded color gamut (ECG) printing in India. While gravure has relied heavily on spot colors, ECG allows converters to achieve a wide color range using a fixed set of process inks. He said that with the rise of digital printing, brands are already familiar with the benefits of CMYK+ approaches, and flexo can deliver similar speed and flexibility. “ECG not only reduces the dependency on spot inks but also speeds up production while maintaining or enhancing quality,” he added.

Changing mindsets

Beyond technology, Smith acknowledged the need to shift industry mindsets. “Converters often fall back on the thinking that ‘this is how we’ve always done it.’ But the market is changing. Adopting technologies like advanced plates and ECG is the future, and those who embrace it will stay ahead.”

Smith reiterated that Miraclon’s approach is not about competing as the “best plate supplier,” but about enabling efficiency across the packaging chain. “Packaging is one area of print with no electronic substitute,” he said. “By helping India’s converters adopt modern flexo practices, we’re supporting brands, printers, and ultimately consumers with packaging that is more efficient, more sustainable, and more competitive.”

With India’s packaging market poised for rapid growth, Miraclon sees flexo’s role expanding steadily. By combining cost savings, efficiency, and sustainability, the company believes flexo can complement gravure while helping the industry respond to shifting consumer and brand demands.