From 14 to 16 September 2022, Syntegon will display its varied food packaging portfolio at the PackEx India at Bombay Exhibition Center in Mumbai. It will be the first time since the beginning of the global pandemic that the company presents its versatile solutions for food processing and packaging at a trade show in India.

Customers and suppliers can look forward to various vertical, horizontal and secondary packaging systems for candies, snacks and powders, as well as sustainable packaging solutions – in keeping with the company’s mission to deliver processing and packaging for a better life. Finally, after sales services will round out at the Syntegon stand H30 in Hall 1. “In the past few years, we have proven that Syntegon is a strong player with a global presence in the packaging industry. At the PackEx India, we will showcase our broad range of solutions and demonstrate how we enable customers to quickly respond to market and product changes,” says Nilesh Vedak, managing director of Syntegon Technology India.

Vertical machines for efficient and sustainable production

One of the highlights of the PackEx India stand are the vertical packaging solutions – visitors will have the chance to take a closer look at the SVE 2520 AR vertical form, fill and seal machine, which can package nuts, extruded snacks or Indian namkeen in airtight bags. With an output of up to 200 bags per minute, the machine is designed to process various products at high speeds for maximum efficiency.

bags per minute. Photo Syntegon

The vertical portfolio at the show will also include an SVI 4000 vertical bagger for packaging powdered food and non-food products in combination with an auger for precise dosing and PHS 2.0 sealing technology – achieving higher fill weights of up to ten kilograms. Additionally, both the SVI 4000 and PHS 2.0 sealing system can process recyclable mono-materials without compromising on production speed – a win-win for manufacturers looking to combine highly efficient processes with more sustainable packaging materials.

From gentle handling to pack style flexibility

wrapper Pack 201 HS

wraps layer cakes and will be shown in combination with a Pack Feeder 4 infeed and a Pack Feeder

4 IB3. Photo Syntegon

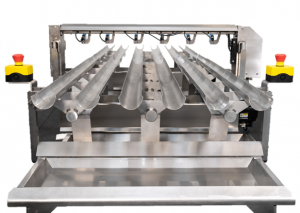

For visitors interested in horizontal packaging solutions, Syntegon will present the flow wrapper Pack 201 HS for wrapping layer cakes at the booth. The machine will be shown in combination with a Pack Feeder 4 infeed and a Pack Feeder 4 IB3. Moreover, the company will showcase Sigpack ZF vibratory channels that allow for gentle handling and function as a buffering system for the processed products, ensuring safe product transport and avoiding product waste.

In addition, Syntegon will also highlight its proven BVK 2000 A form, fill and seal machine for flow wrapping confectionery products like hard candy at high speeds. Manufacturers benefit from the flow wrapper’s efficiency and reliability, as well as fast changeovers that allow them to process a variety of products and pack styles.

Complementing Syntegon’s versatile portfolio, the company also offers secondary packaging solutions – for example, the Sigpack TTME cartoner is suitable for a variety of carton formats and sizes. At the booth the visitors can take a closer look at different packaging samples for a broad area of applications.

Service agreements for customized support

The PackEx stand will also feature Syntegon’s extended Service and Digital Solutions portfolio. The company now offers revised Service Agreements with a range of service levels, including maintenance, spare parts management, remote services, and training. The flexible packages provide customized support at a fixed price over predefined time periods. “With our large portfolio of machines and services, we can provide customers with optimal support throughout the entire lifecycle of their machine and offer solutions tailored to their individual needs,” says Nilesh Vedak.

(This story was originally published on 8 August 2022)