Asahi Photoproducts, a specialist in flexographic photopolymer plate development, has announced that The Oldham Group has become the first in the US to install the innovative AWP Tap Water System. This installation marks a significant milestone in Asahi’s ongoing ‘Road to Solvent Zero’ initiative, offering the flexographic industry a sustainable platemaking solution with no solvents, no detergents, and minimal environmental impact.

The AWP Tap Water System is set to be available starting 1 July 2025. With this breakthrough, Asahi strengthens its commitment to helping the flexo community transition to more sustainable and efficient production processes that reduce environmental impact while maintaining premium print quality.

Eco-friendly solution

The new AWP Tap Water System installed at The Oldham Group is designed to offer a sustainable solution for small-format platemaking needs. It comprises three integrated innovations:

AWP Tap Water Plate: A water-washable plate requiring only tap water for processing, eliminating the use of VOC solvents and detergents. It delivers outstanding print quality and measurable improvements in Overall Equipment Effectiveness (OEE), ideal for flexible packaging and label applications in small format.

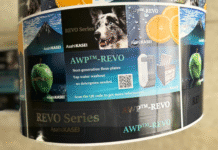

AWPTM-2530AA Plate Processor: A compact, all-in-one plate processor developed to meet the highest environmental and print standards for smaller plate sizes. With a user-friendly interface, it enhances fine screening performance and precise color reproduction, offering smooth integration into small production environments.

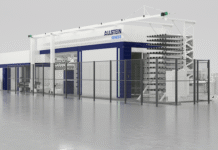

AWP-LOOP Petite: A closed-loop water recycling unit. Using Asahi Kasei’s Microza™ filtration technology to reduce wastewater and operational costs, complementing the tap water plate technology and enabling an eco-friendly platemaking process.

Together, these innovations deliver a new benchmark for small-format sustainable flexographic platemaking, supporting printers that are seeking to eliminate solvents while maintaining excellent print performance.

“We believe Asahi’s goal to solvent ‘Zero’ and their commitment to sustainability has finally led to the release of a water washable plate using only tap water,” said Jerry Collins, vice president at The Oldham Group. “This is a major accomplishment that the flexo industry has been waiting for — it delivers excellent press performance and a sustainable reduction of the printer’s carbon footprint. A tap water solution that eliminates the need for detergents and potassium carbonate reduces a printer’s environmental impact. This is a big win for the printer and the environment. It is now the perfect time for printers using other platemaking alternatives to switch to a tap water platemaking solution.”

Asahi’s Road to Solvent Zero

The installation of the AWP Tap Water System represents another critical step on Asahi’s ‘Road to Solvent Zero’ — an initiative dedicated to eliminating VOC-based washout processes and improving production environments across the flexographic industry.