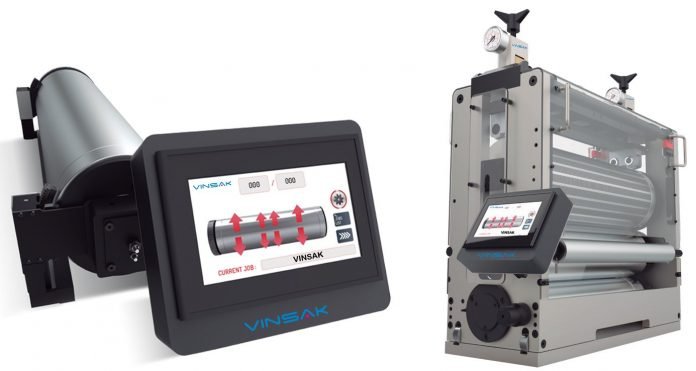

The E-Diff system from Vinsak, powered by Tecnocut of Spain, is a revolutionary product in controlling die-cutting systems in web presses used to produce labels. The system allows an electronic variable adjustment with micrometric precision (+/- 0.001 mm) between the anvil roll and the magnetic cylinder. Unlike similar mechanical products on the market, which have a larger step size, need regular mechanical adjustments and lubricants, and are not as accurate, the E-diff system claims to be miles ahead in technology. The system will replace the existing anvil roller in the die-cutting station, allowing a flexible die to perfectly cut into pressure-sensitive materials virtually independent of the liner thickness (glassine, kraft, synthetic) with a maximum + and – correction of 0.1 mm. Vinsak says the unique E-Diff system can electronically change the air gap in three different ways: Operating side, Driving side, and Overall. Key advantages of the E-Diff system: The E-Diff system can (normally) be installed by simply replacing the anvil roller. Clear HMI (touchscreen). Initializing function to return to zero (starting) position automatically. Possibility to store…

Choose your subscription to read more

Trial

- ₹ 0 for 4 weeks*

PSA Plan 1

- ₹1,500.00 for 1 year*

PSA Plan 2

- ₹2000 for Year*

PSA Plan 3

- ₹3,600.00 for 2 year*