Alwan Color Expertise, an enterprise in colour management and process control software announces version 7.6.0 of its leading colour management and ink-saving software Alwan ColorHub. This new version has been optimized for digital printing presses as it offers increased spot colour accuracy, ink savings, and PDF-VT processing speed.

“Alwan’s PDF colour server Alwan ColorHub has been originally designed in 2001 to help conventional printers better predict and control the colour and cost of their production.

“With more than 1,500 servers used daily to optimize millions of jobs, Alwan ColorHub is considered today as a leading software in its category. However, the fast increase of high-volume digital printing and our partnership with Konica Minolta for their flagship digital press AccurioJet KM-1 taught us that there is a strong need and room for improvement for digital presses as well.”

“Alwan ColorHub Version 7 – and even more so with version 7.6.0 – addresses digital printing specifics and takes colour spot accuracy, ink savings, and production speed to unmatched levels,” says Elie Khoury – Alwan founder and president.

Spot colour accuracy thanks to hydra profiling technology

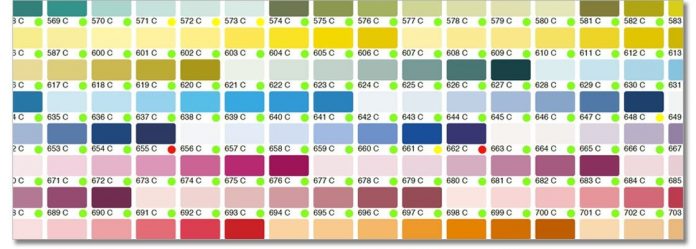

Matching spot colours on a digital press is a challenge as digital presses do not have spot ink units as conventional presses do.

Therefore, moving jobs containing spot colours from conventional to digital printing is often disappointing or not done at all.

With its patented hydra profiling spectral technology, Alwan ColorHub is able to create a profile of the production device, to predict its spot color reproduction capabilities, and use Hydra profile for the spot to device colour conversions.

Result is that 10%+ more spot colors are matched with ∆E00 2 compared to conventional CIELAB based profiles.

More ink savings thanks to minimum TAC and ink usage colour separation technology

Digital printers use digital ink, also called digital gold due to their price.

Moreover, these inks are device dependant and do not have the same colour or characteristics as conventional inks do.

For these reasons, conventional UCR/GCR black-generation-based colour separation is not optimal for digital inks.

Alwan’s unique Minimum TAC and Ink Usage (MTIU) technology uses Hydra profiles to optimize the colour separation for digital inks and digital devices.

Result is 10%+ more ink savings and colour accuracy compared to conventional GCR and CIELAB based colour separation.

Production speed thanks to multi-page, multi-thread processing technology

Some digital printing applications such as books and variable data require special processing strategies in order to use the full power of the used computer or server.

Alwan ColorHub 7+ versions use new multi-processor, multi-thread processing technology that optimizes PDF processing speed.

Result is a decrease of processing time by a factor of 2 to 10 depending on the computer and the job.

“When we recently interviewed a representative sample of our users, we found out that most of them were able to move previous offset jobs containing spot colours to digital printing without any problem.

“On the contrary, their feedback was that, because of decreasing print numbers and increasing colour expectations, they were more confident, and making more money now printing spot colours using their digital press with Alwan ColorHub,” says Elie Khoury – Alwan founder and president.

Alwan Color Expertise is a worldwide enterprise in colour management, process control, and standardization software.

Founded in 1997 by industry international expert Elie Khoury, Alwan develops, distributes, and supports innovative software solutions allowing actors from the graphic arts industry improve margins through standards and automation.

Alwan Color Expertise offers solutions across the printing workflow, including color measurement (Alwan ToolBox), ICC profiling (Hydra Profiling), color management (Alwan ColorHub), process control (Alwan PrintStandardizer), and quality control and reporting (Alwan PrintVerifier).

Designed with the end user’s expectations at heart, all these products are workflow independent and deliver cost-efficient and high-quality results.

The suite of software proposed by Alwan are compatible with all printing processes (offset, digital, flexography, gravure) and ink palettes (CMYK, spot, multicolor).