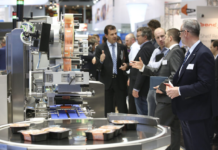

Flex Films, the global film manufacturing arm of flexible packaging materials and solution company Uflex, will be exhibiting its myriad innovations in the field of film manufacturing at interpack 2017. At the mega event the company will have six zones: Sustainability, Speciality, Lidding, Barrier, PP (OPP & CPP) Family and Aesthetics, and Anti-Counterfeiting.

Sustainability

Sustainability holds a special place in all business operations of Flex Films. Strong emphasis is laid on fostering down-gauging, light-weighting, reduction at source and design optimization in all its creations. Some of the major highlights of this zone will be recycled polyester film; oxo and bio-degradable films and green polyester film (Green PET) among others. This film has been internationally honored for its sustainability quotient.

Speciality

This zone will showcase the latest innovations like Twist (TST); Shrink (SPH); Easy Stackable (ESB); Digital Printing (PDP); UV Curable (UVC); Electronic Goods Wrapping (MTG-AS-B/M) Film; Special Polyester Film for Alu-Alu pharma laminate; and Easy Tear (IET) Films. One of the much sought after substrates that will be on display at Interpack this time around is a special polyester film that has successfully replaced BOPA and PVC substrates from a typical Alu-Alu laminate used in pharma packaging thereby serving as a game changer.

Lidding

Flex Films has engineered suitable substrates that pave the way for smooth and easy lid-opening. In the lidding section at Interpack the company will be displaying Isotropic (IST) and Peelable (TPA) films among several others. Isotropic (IST) Films are polyester substrates having balanced properties that ensure the film does not tear abruptly.

Barrier

Flex Films has made substantive headway in engineering high barrier substrates. Some of these that can be seen at Interpack this time around are AlOx (PLX & PGX); Bag in Box (LBP-M); High Barrier MET PET (EBP – M) and Super Barrier Corona (PGB) Films among several others.

PP (OPP & CPP) Family

Flex Films also manufactures different variants of Oriented Polypropylene and Cast Polypropylene Films. Some of these films that will be on display at Interpack are: Ultra Barrier OPP (TUB-M); Low SIT (TLS); Anti-fog OPP (TAF); Retortable CPP (CPR); Deep Freeze CPP (CDF) and High Barrier CPP (C-CXB-PZ-M) Films.

High Barrier (C-CXB-PZ-M) is a metallized CPP film with metal deposition on the corona treated surface, while the other side being sealable. This film demonstrates a broad hot tack window, excellent barrier properties and low seal initiation temperature. The film finds extensive use in manufacturing packaging material for snacks and biscuits.

Aesthetics and anti-counterfeiting

Flex Films will display Holographic and Fresnel Lens Embossed Films among other brand protection solutions. Other pigmented special effect films from the polyester and polypropylene families in high gloss and matte variants will also be seen at Flex Films’ stall at Interpack 2017.

Flex Films will display Holographic and Fresnel Lens Embossed Films among other brand protection solutions. Other pigmented special effect films from the polyester and polypropylene families in high gloss and matte variants will also be seen at Flex Films’ stall at Interpack 2017.

Praising Messe Dusseldorf’s initiative of congregating all stakeholders of the converting and packaging industry under one roof, Ashok Chaturvedi, chairman and managing director, Uflex Limited said, “The collective wealth of experience in terms of product innovation for the converting/packaging industry that will be on display at Interpack 2017 is truly praiseworthy. I am glad that Flex Films will be showcasing its most contemporary and innovative products for the global converting industry. After-all the art of converting starts with the science of manufacturing the film.”