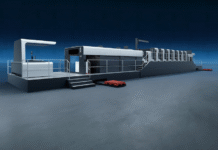

Manroland Sheetfed planned to launch three new presses at drupa. Since drupa didn’t happen this year and got postponed to 2021, the company has brought the new presses to market immediately with a strategy to target specific carton segments. In the process of adding two variations in the Evolution series, its successful Roland 700 Evolution press has become the Roland 700 Evolution Elite. The company claims the 700 Evolution Elite is the world’s most technologically advanced sheetfed offset press, which is available in 16,000 and 18,000 sheets an hour configurations.

The technologies that differentiate the new 700 Evolution series of presses include a new feeder head and cylinder geometry. The cylinder geometry enables the Evolution series presses to run at rated speeds whether or not they are configured with UV curing.

The new 700 presses – Evolution Speed and Evolution Lite

The first of the new 700 Evolution variations is the 700 Evolution Speed, rated to run at 20,000 sheets an hour. The Evolution Speed model includes the appropriate automation features and curing options needed for the highest configuration presses. Moreover, like all the manroland presses, it is designed to be run at the full rated speed even when configured with UV curing on substrates of suitable quality.

The second new model is the Roland 700 Evolution Lite, which runs at 15,000 sheets an hour and dispenses with automatic plate loading and blanket washing. The entry-level press, which only has manual plate loading, is not available with UV curing from the factory. The 700 Evolution Lite is the long run carton printing machine for emerging markets.

Manroland Sheetfed’s 700 Evolution Lite is available in fixed configurations of 4, 5, and 6 colors with or without a coater. The new Lite model aimed at medium and long run monocarton printers dispenses with several automation features to make it price competitive.

Roland 900 Evolution

The newest manroland sheetfed press to join the family is the Roland 900 Evolution, which marks the company’s re-emergence in the very large format platform category it once dominated. Based on the Evolution platform, this machine will be available at a speed of 16,000 sheets an hour in three very large-format sizes – 135 cm, 142 cm, and 162 cm.

Langley Group’s turnaround of Manroland Sheetfed

In terms of its profitability and cash position, Langley Group has completely turned around the Manroland Sheetfed Division with revenue of €203.5 million in 2019. At the end of 2019, it had orders on hand of €61.2 million compared to €27.4 million at the end of 2018. In other words, the order position was compelling the company and its 1,472 employees to work at the highest level since Langley acquired it in 2012.

As its chairman, AJ Langley, said in the company’s recent annual report, “The order book is now at a healthy level with production at its highest level since we acquired the business in 2012.” The CEO of Manroland Sheetfed, Rafael Penuela, had said earlier in 2019 as he thanked customers for their support, “Our production line in Germany is running at full capacity at least till next March.”

Lower cost base

Langley, who is extremely forthright in his communication, especially as to the company’s strengths and viability, added in the annual report, “The Manroland business has a lower cost base and, in contrast to its competitors, is saddled with neither debt or disproportionate overhead costs. The company’s presses are highly regarded in the market, and Manroland’s reputation universally recognized and the shareholder is patient.

“During our stewardship of the company, investment in product development has continued unabated, and 2019 was no exception. In 2016, the company unveiled its Roland 700 Evolution press, developed entirely during our stewardship and formally launched at Drupa [2016], is now widely regarded as ‘best in class.’”

Drupa 2020 was well-timed for the company to unveil its latest offerings. And since the exhibition is postponed by a year, the company felt it was wiser to let its customers know about its new models, which better target specific customer segments, as soon as possible.