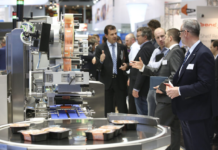

At interpack 2017 on the HP stand, TRESU Group will demonstrate the productivity of its iCoat flexo coater for applying added-value varnishes to digitally printed folding cartons and synthetic materials, seamlessly inline with an HP Indigo 30000 digital press.

TRESU iCoat applies TRESU’s private label iVarnish range of UV-curable or aqueous varnishes, optimised to offer excellent adhesion properties on both plastic as well as board substrates. It has a maximum speed of up to 4,600 sheets per hour, handling substrates of maximum format 750 mm x 550 mm in paperboard and metallised boards between 250 micrometers and 600micrometers. It also accommodates PVC and polypropylene substrates up to 630 micrometers, and PET substrates up to 400 micrometers. The coater also comes with quick-change sleeve technology and automatic chamber cleaning, enabling varnish changeovers within minutes. Its sleeves assure smooth production without mis-registration at maximum speeds equivalent to that of the HP Indigo 30000.

“Coating is a vital post-print stage in the digital packaging printing process, ensuring the finished product is both resistant and aesthetically appealing. The TRESU iCoat coater integrates perfectly with the HP Indigo digital press, applying full and spot varnishes in perfect register with minimal makeready time, and the result is a high-speed single-pass line with minimised waste or logistics,” Kim Krintel, vice president, TRESU Digital Solutions says.

A TRESU innovation for the digital workflow to be used with TRESU iCoat demonstrations at interpack 2017 is TRESU iTape, a double-sided adhesive, developed in partnership with Lohmann Bonding Engineers, of Neuwied, Germany. Benefits are superior dot gain control and varnish transfer, and fast frictionless demounting, eliminating the possibility of causing sleeve damage. Besides the TRESU iCoat coater, TRESU provides a complete workflow of consumable products and equipment including coating media and tapes, coating circulators and sleeve cutters. There are also twin-unit and inkjet coating machines.

A TRESU innovation for the digital workflow to be used with TRESU iCoat demonstrations at interpack 2017 is TRESU iTape, a double-sided adhesive, developed in partnership with Lohmann Bonding Engineers, of Neuwied, Germany. Benefits are superior dot gain control and varnish transfer, and fast frictionless demounting, eliminating the possibility of causing sleeve damage. Besides the TRESU iCoat coater, TRESU provides a complete workflow of consumable products and equipment including coating media and tapes, coating circulators and sleeve cutters. There are also twin-unit and inkjet coating machines.

The TRESU iCut plate cutter provides a fast means of imaging flexo plates for the post-print spot coating of digitally printed folding cartons. TRESU iCut is designed to process the same software as the digital printer, as well as the accompanying analogue coater. Processing times are less than ten minutes. Once imaged, the plate, together with the sleeve, are ready to be mounted on the coater for production.

TRESU’s iCoat 30000 TWIN, featuring two flexo coating units, applies a combination of aesthetically appealing spot, line, matte and gloss varnishes in a single pass.