UFlex has announced several product innovations in the second quarter ending 30 September 2022. These include three innovations from the flexible packaging business.

Nat Habit organic natural beauty products

The flexible packaging business division has developed a special high-barrier packaging format that prevents degradation and preserves the natural properties of organic natural beauty products while increasing their shelf life. Nat Habit, a startup in the natural beauty and wellness space, required a packaging solution for its natural preservative-free henna paste. UFlex’s flexible packaging business division created a unique stand-up, center-seal pouch with a side gusset. This pouch provides an ultra-high barrier against moisture, gases, and UV rays, and assures protection to the natural ingredients of the henna paste.

It extends the shelf life of the product by preventing it from oxidative degeneration and delaying bacterial growth, thus preventing it from contamination. The unique lacquer coat provides a very organic feel that resonates with the brand positioning. Owing to the packaging solution and the performance of the structure, the brand has apparently witnessed a three-fold increase in demand since its launch, according to Uflex.

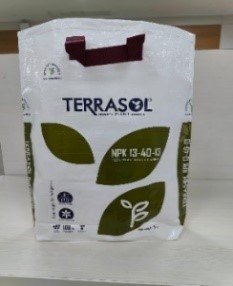

MPP and WPP large packaging for Terasol fertilizer

Photo Uflex

Taking note of its pioneering capability in developing WPP, Terasol, a large player in agriculture products, approached the UFlex team to develop a packaging solution with added security features that not just give a facelift to the pack but also prevent it from security risks during transit. The UFlex flexible packaging research team developed a packaging structure with MPP/POLY PROPYLENE- (EXTRU) to pack water-soluble Terasol fertilizer.

The packaging structure of a block bottom pouch with a seal of quality via hot foil stamping was well received by the brand. The packaging structure has successfully passed mechanical tests and delivers on the aesthetics requirements of the brand.

High barrier BOPET film F-AFR-M

In order to meet the exceptional barrier requirements for oxygen and moisture-sensitive products that typically include milk powder, coffee, or beverage packaging, the flexible packaging films business division of UFlex has developed a barrier BOPET film ‘F-AFR-M’ with metallization on one side and the option of corona treatment on the other side.

FAFR-M offers a metal bond strength of more than 600gm/25mm for easy handling and machinability. Owing to its high oxygen and moisture barrier properties and easy recyclability, the film has emerged as a successful replacement for aluminum foil used in dried packaging applications, which enables brands to come one more step closer to their sustainability goals.