We are hearing about the application of offset technology in the field of flexible packaging printing for quite some time now. Though neither offset nor its application in flexible packaging are new, there seems to be a renewal of interest in using this technology on film laminates. The idea is gaining ground in Europe and could spread further in the coming years.

Before the Covid-19 outbreak, packaging was growing at a phenomenal rate across the world, and more so in India. Some industry forecasts predicted a growth of 19% in the next 4-5 years, mostly because of the trends like smaller family sizes, a wide array of options, and fragmentation, which have led to a demand in differentiated packaging.

However, looking at the current scenario, we see the world is going through very different and challenging times. With the economic slump resulting from Covid-19 lockdown, coupled with salary cuts and job losses, it appears that the ‘new normal’ would be quite different from the one we had become used to. According to a report published by the financial daily Mint, FMCG firms anticipate that after hoarding large packs of staples and home care products during the first phase of lockdown, consumers will now prefer smaller pack sizes. They will look for newer and cheaper brands that are readily available nearby or online and will prefer a hygienically packaged product, thus avoiding the risk of infection.

Under the circumstances, innovative, affordable, and right quality products that are available in multiple formats are likely to gain demand as consumers increase their consumption of hygienic products. So, what matters most is the ability of the packaging printer to switch from one job to another with swift turnaround times and do so economically – at a competitive cost.

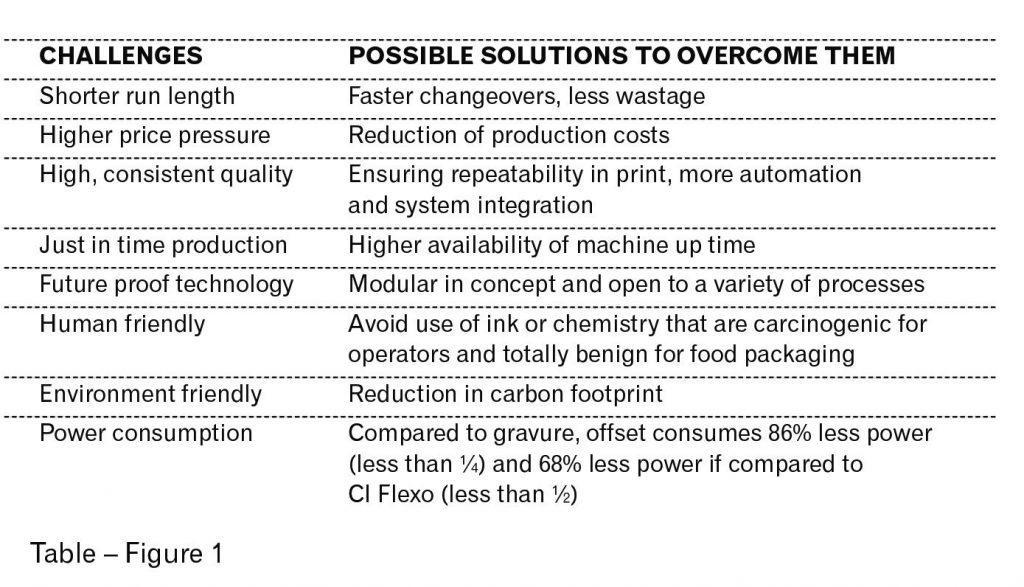

Production challenges

Let us take a look at the challenges that the printer would face in these changed circumstances and the possible solutions.

Does offset provide us with a viable solution?

Yes, of course, offset printing using electron beam (EB) curing works well for flexible packaging. It addresses all of the above challenges, but it also provides additional benefits like easy operability and usage of intelligent networked processes complying with Industry 4.0 protocols and standards. Offset printing on flexible substrates using EB curing has the advantage of using non-UV inks or solvents free from carcinogenic photoinitiators and VOCs. This makes it immensely popular in segments like food packaging.

Cost-benefit analysis

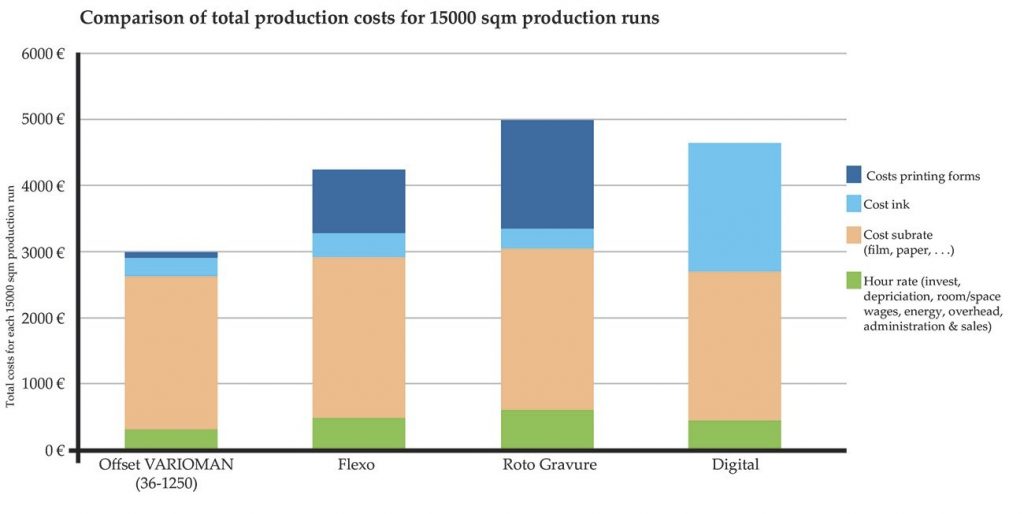

But how does offset provide a price advantage vis-a-vis gravure, which is the most popular technology used in flexible packaging? To understand the costs, let us first take a look at the infographic given below. Figure 2

As reflected in the bar graph, while the substrate costs remain the same for all the processes, the area where offset scores well is in the cost for printing forms – the image carriers that must be produced and loaded on the presses for each color. While gravure uses electronically engraved cylinders – that are not only expensive and time-consuming to make and use heavy metals for plating that are hazardous, offset has the advantage of using cheap anodized aluminum plates made just in time in minutes on a modern CtP device. The difference brings down the running cost of offset by almost 25% compared to gravure for a run of 15,000 square meters. (In India where gravure is dominant, and gravure cylinders are produced quite competitively compared to digitally imaged flexo plates, the comparison of flexo and gravure may vary slightly.)

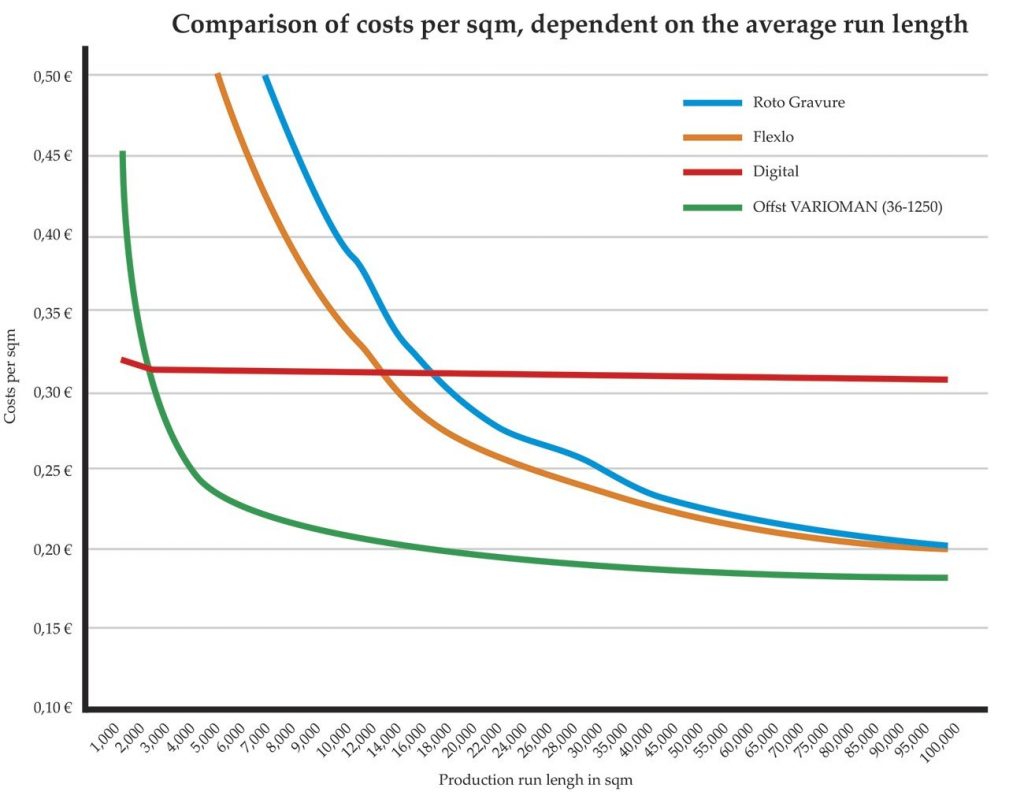

The effect of run lengths on the competitiveness of various processes for flexible packaging printing

To better understand the competitiveness of the various processes capable of printing on flexible laminates, we compare the costs for a run-length up to 100,000 square meters—figure 3.

We can see from the above graphs that for any run-length of less than 3000 square meters, the use of digital printing is a no-brainer. No other technology can match it. For run lengths between 3,000 and 100,000 square meters, offset is unbeatable. In any run length above 100,000 square meters, the price gap between gravure and offset comes closer, but offset is still lower.

manroland Goss web systems based on its decades of experience in offset printing has developed the Varioman f:line, especially for flexible packaging printing with a high level of automation. It has created a technology that specifically avoids the weak points inherent in other processes.

The offset-based variable-format printing units combine low printing plate costs and high print quality, and in conjunction with the unique Pecom-X automation system, can achieve particularly short make-ready and changeover times, at low waste levels.

The optional combination of printing technologies such as gravure and flexography in the same line results in the additional overall advantages of a hybrid system. With the additional gravure units, the print product can be supplemented with opaque white or gold and silver decoration at a lower cost and the requisite high quality. The Varioman was therefore developed from the very beginning as a platform concept that can be optimally configured to meet customer’s specific requirements.

Demographics, automation and the pandemic are compelling

Thus we can say that the successful flexible packaging printers of tomorrow need to be technology agnostic. Their future choices need to be sagacious to reconfigure their print infrastructure with an eye on changing market and environmental needs. With Artificial Intelligence and IoT playing a more prominent role than ever before, we are entering a phase where the printing machine and the user would almost develop a symbiotic relationship. It is more than likely that the leading packaging printers who already have both gravure and flexo and are looking at digital will also look at the new option of offset with EB curing. Can they afford to remain complacent?

Editors note – This article contained a mistake in Figure 3 when originally uploaded which has been corrected on 1 July 2020 at 1110 hours India time. The error is regretted.

I think the hourly rate shown for the Offset VARIOMAN compared to Flexo and Gravure is not correct. It is not easy to print a full solid with fine reverse text by offset on clear film due to the ink water balance needed to maintain the reverse in long runs. Metallic and white are not easy to print by offset with desired depth and will need additional flexo or gravure unit for same. This will defeat advantage of making offset CTP plates faster, as you need to wait for few hours to few days to get a flexo plate for one color or gravure cylinders.

Developing skills for web offset printers for packaging applications will be a challenging task.

Dear Mr. Samant,

Thank you for your comments. Our reply is as below –

By hourly rate, I assume you indicated towards the Hour Rate in Fig 2. Amongst others, they include the investment cost, overheads as well as energy cost. As indicated in the article, the energy costs of the Varioman are less than 1/4th as compared to Gravure. There is also the added benefit of no requirement of solvent recovery. Due to the level of automation in line with Industry 4.0 standards, the requirement of manpower is minimal.

As far as printing fine reverse is concerned, we have been able to print less than 0.1 mm. As far as printing certain metallic colors or white, I agree with you to a certain extent that they are better produced in gravure and that is the reason why we have created a hybrid equipment if the requirement of the client is such.

As far as skills of operation are concerned, our level of automation ensures that the individual skill levels are not so important any longer. Web Offset as a technology is not new either.

Would also like to add that the first Varioman is already in production and we are getting very good feedback from the client. Based on the results of the first, we have also been able to bag the order for the second one. In case you are interested to see the samples, kindly get in touch with us. We would be eager to help you.