UPM Raflatac offers high-quality self-adhesive paper and film products, helping brands, designers, and printers in selecting the optimal label to bring their packaging designs to life. Through its innovative solutions, the company aims to enhance the sustainability and circularity of the label material’s value chain.

In India, UPM Raflatac – which opened a new slitting and distribution terminal in Mumbai in March 2024 – provides a range of products, including general category chromo label stock, filmic, and specialized application labels, catering to various industries such as food, pharma, logistics, FMCG, retail, textile, wines, spirits, beverages, durable and automotive segments, said Suresh Valecha, country manager – India, UPM Raflatac.

“Alongside facilitating transactional exchanges with converters, we offer value-added services for label customization and developing tailored products to critical applications. Our sustainable approach aims to boost production efficiency while minimizing customer pain points and ensuring satisfaction,” Valecha added.

UPM Raflatac is supplying these products in the entire Indian subcontinent along with Bangladesh, and Sri Lanka with dedicated sales and marketing teams based in India, Valecha said, adding that all major converters and end users in India make up their customer base.

Sustainable label stock solutions for the Indian market

As one of the world’s leading producers of self-adhesive label materials, UPM Raflatac plays a crucial role in driving more sustainable labeling solutions, free of fossil fuels, he said, adding that the solutions it offers to its customers are the product of continuous development of innovative future solutions.

“Our commitment to sustainability allows our customers to provide the best sustainable options to consumers without compromising end-product performance. We are contributing to a critical mission – a future beyond fossils. Sustainability is at the core of how we operate,” he added.

UPM Raflatac is contributing to UPM’s target to reduce carbon emissions by 30% by 2030 in its value chain, operations, and products, with the ultimate aim of achieving carbon neutrality by 2050, he said. “In India, we offer 100% FSC-certified products, ensuring the highest standards of sustainability. Employing the principles of reduce, recycle, renew, and reuse, we empower brand owners and printers to make a positive impact with sustainable labels,” he added

UPM Raflatac actively reduces label stock thicknesses to alleviate the burden on our renewable resources and minimize paper/film consumption throughout the value chain. In addition, the company’s focus extends to facilitating the reuse of packaging containers across various industries, including glass, PP, HDPE, LDPE, or PET types. UPM Raflatac has also introduced a wash-off adhesive product range for glass and PET containers, along with a specially designed adhesive (PURECYCLE) for HDPE/LDPE containers.

In India, the company has introduced 100% recycled-based chromo label stock, which incorporates 30%, 70% or 90% recycled content based on PP/PE/PET, tailored for different industries. UPM Raflatac’s recycled portfolio holds certifications from RECYCLASS and APR, along with food-grade certification for future applications in food secondary packaging in India, Valecha shared.

UPM Raflatac’s latest innovation, Forest Film, is produced using 100% non-renewable sources, offering a sustainable alternative that reduces dependency on renewable resources across packaging applications, he told Packaging South Asia.

New slitter terminal in India

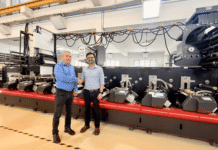

UPM Raflatac opened a new slitting and distribution terminal in Mumbai, India in March 2024. The new facility is aimed at further improving service and quality to UPM Raflatac’s customers and strengthening the relationships in the region.

“Customers welcomed the step of the new world-class terminal, which will enhance production capacity, reduce turnaround time, leading to better service, shorter lead times, and most importantly happier customers,” Valecha said, adding converters and end-users are welcome to visit the new terminal and see for themselves what goes on behind the curtains of label-stock production, conversion, and deliveries.

“India is in a very good space now, whether it is concerning the economy, consumer spending or industry growth. We have a huge consumer base with very low packaging per capita consumption as compared to the rest of the world,” Valecha shared.

“Packaging and labels are an integral part of products, and consumers want exquisite and sustainable packaging. So, we want and will cater to end-users in all parts of South of Asia. We keep a tab on growth engines and on accelerating revenues to set up the base soon other than in central India,” he concluded.